Application Note B-XRI1016

Introduction

Aluminum laminated films are used in the packaging of pharmaceuticals and foods, as well as in the packaging of lithium-ion batteries. During manufacturing or processing the films into packaging, abnormalities such as pinholes and asperities may occur. Since visual inspection of small pinholes is difficult, and the cause of asperities cannot be determined by visual inspection, it is necessary to observe the internal structure of such abnormal areas of laminated films with high resolution and in a non-destructive manner. Micro X-ray CT allows non-destructive observation of the internal structure of a sample with a resolution of several µm, which is useful for the identification of abnormal areas and investigation of the cause. In this example, we performed a CT scan of an aluminum laminated film with asperities and observed the internal structure.

Example of measurement and analysis

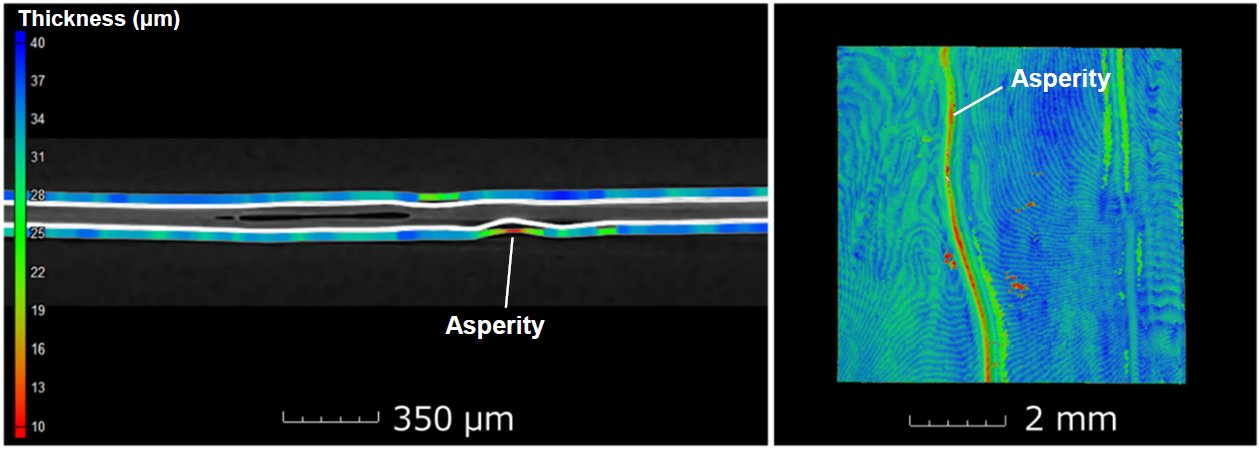

A CT scan of a 150 µm thick aluminum laminated film with asperities was performed at 3.5 µm/voxel. The CT cross-section image and 3D image of the asperities are shown in Figure 1. In the cross-section image, the aluminum layer is shown in white, the resin layer in gray, and the voids in black. In the area with asperity, the aluminum layer rippled, creating a void between the aluminum layer and the resin layer (Figure 1 (left) a). In addition, peeling of the resin on the inner side of the aluminum was observed near the asperity (Figure 1 (left) b). The thickness of the outermost surface resin layer was uneven, so the thickness distribution was color-coded in the cross-section and 3D images (Figure 2). The thickness of the resin layer in the asperity area is less than 10 µm, while the thickness of the resin layer in other areas is about 30 µm.

Figure 1: The CT cross-section image (left) and 3D image (right) of an aluminum laminated film

Figure 2: Thickness distribution of the resin layer in the CT cross-section image (left) and 3D image (right)