Application Note RACCT9004

About the sample: Particleboard

Particleboard is engineered wood and made by compressing and extruding woodchips with a binder. It is less expensive than conventional wood or plywood and is used often to substitute them to reduce cost. Particleboard is generally less dense but more homogeneous than conventional wood. However, the density often varies from the surface to the center area of the particleboards. X-ray CT (computed tomography) can be used to see the texture of the woodchips and calculate the packing density of materials like particleboard.

Analysis procedure

- In this example, a piece of particleboard used in furniture was scanned using a micro-CT scanner, CT Lab HX.

- The cross-section was observed for texture and density variation.

- The packing density was calculated at the near-surface and center of the particleboard.

1. CT scan

About an inch size piece of particleboard was scanned to produce the 3D grayscale CT image.

2. Cross-section observation

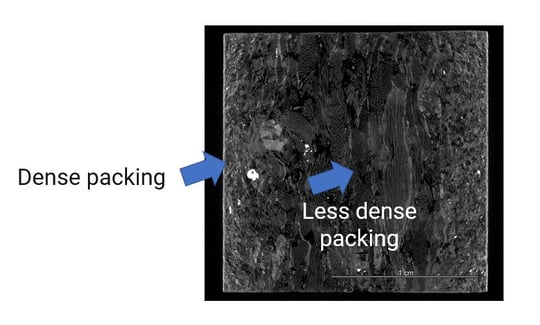

The gray level represents the density of the material. A cross-section perpendicular to the surface of the particleboard is shown in the figure. The woodchip appears lighter gray while the air appears black. The texture (fiber direction) of the woodshop varies depending on the location. It appears dense in the near-surface area and less dense towards the center of the board.

3. Packing density calculation

In the 3D rendered view, red to green indicates higher packing density, and blue indicates lower packing density. Two representative slices are also shown with the local packing densities, 98.7 vol% and 80.9 vol% at the near-surface and center areas, respectively.