Application Note POLYMER014

Introduction

Vinyl acetate polymers such as PVA, polyvinyl acetate (PVAc), and polyvinyl butyral (PVB) have excellent water solubility and plasticity and are used in diverse applications such as adhesives and binders. However, these materials exhibit complex pyrolysis behavior when heated, which can lead to unexpected reactions at processing temperatures and in safety design. TG-FTIR can identify the evolved gas components released as pyrolysis progresses in real time. It is possible to improve the reliability of heat resistance evaluations and process design.

Thermal analysis

| Analysis: | Parts and end products |

| Use: | Process control, failure analysis, quality assurance |

| Analyzed materials: | Polyvinyl alcohol (PVA) |

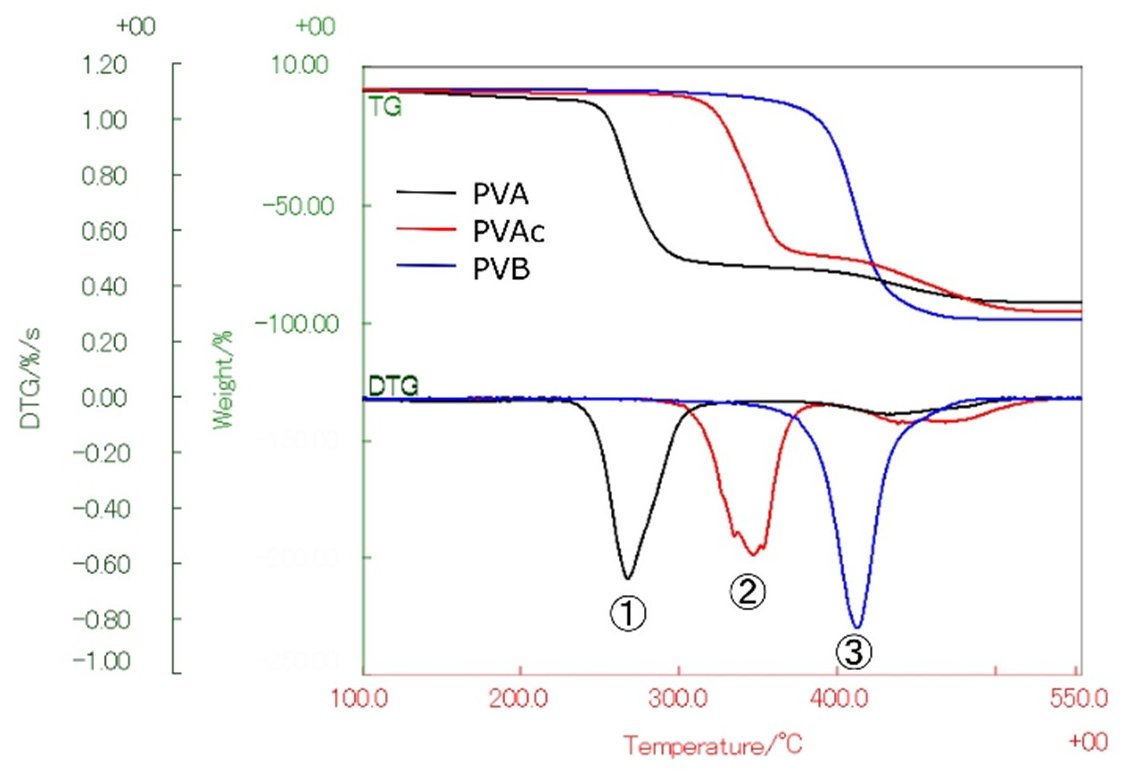

Figure 1: TG and DTG curves of PVA, PVAc, and PVB

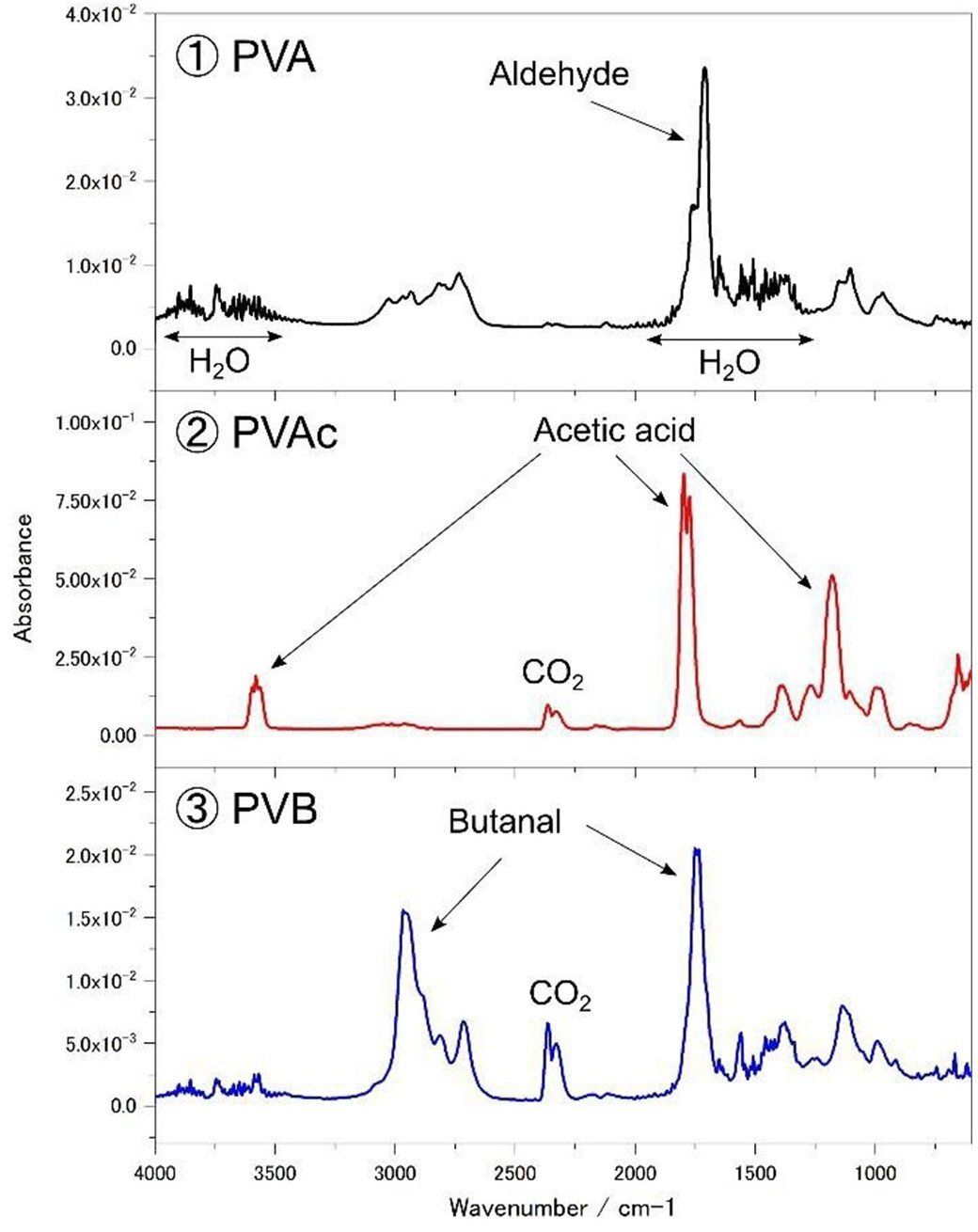

Figure 2: IR spectra at the peak temperature of DTG.

Conclusion

The TG curves of PVA, PVAc, and PVB show that the decomposition temperatures of PVA, PVAc, and PVB are higher in that order, and PVB has the highest heat resistance. Simultaneous FTIR measurements also identified the reaction products during mass loss. Thus, TG-FTIR can visualize the progress of decomposition and the gases produced, which are difficult to capture by weight change alone, and is effective for reviewing production conditions and making decisions on safety design.