Application Note POLYMER016

Introduction

Degradation evaluation of rubber materials is essential to ensure reliability and safety during long- term use. However, conventional indicators such as appearance and hardness may overlook minute degradation due to initial changes and thermal history. TMA can measure minute shape changes such as thermal expansion and contraction. This allows for more accurate decisions in material selection and life prediction.

Thermal analysis

| Analysis: | Parts and end products |

| Use: | Process control, failure analysis, quality assurance |

| Analyzed materials: | Fluoroelastomer |

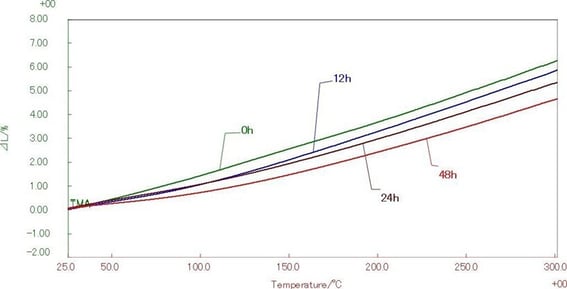

Figure 1: TMA measurement results of fluoroelastomer for each holding time at 300°C

Conclusion

The expansion coefficient showed a tendency to decrease as the holding time at 300°C increased. In general, it is believed that rubber hardens in the early stages of thermal degradation, and these results suggest that it is possible to detect signs of early degradation through minute changes in shape. TMA can be used to quantitatively identify such changes that are difficult to detect by appearance or hardness, and thus is an effective means of improving the accuracy of judgments in evaluating the durability and predicting the service life of materials.