Application Note POLYMER013

Introduction

Slight differences in the shape of a molded product can affect the feel of operation and assembly accuracy. However, the differences are not always visible to the naked eye, and in many cases, dimensions and tolerances on drawings alone cannot explain design or quality defects. Micro X-ray CT can acquire micron- level three-dimensional data without destroying the sample, allowing quantitative comparison and evaluation of shape differences between different molded products.

Non-destructive imaging

| Analysis: | Parts and end products |

| Use: | Process control, failure analysis, quality assurance |

| Analyzed materials: | Plastic airtight container |

| Analysis software: | VGSTUDIO MAX (Measured/actual value comparison) |

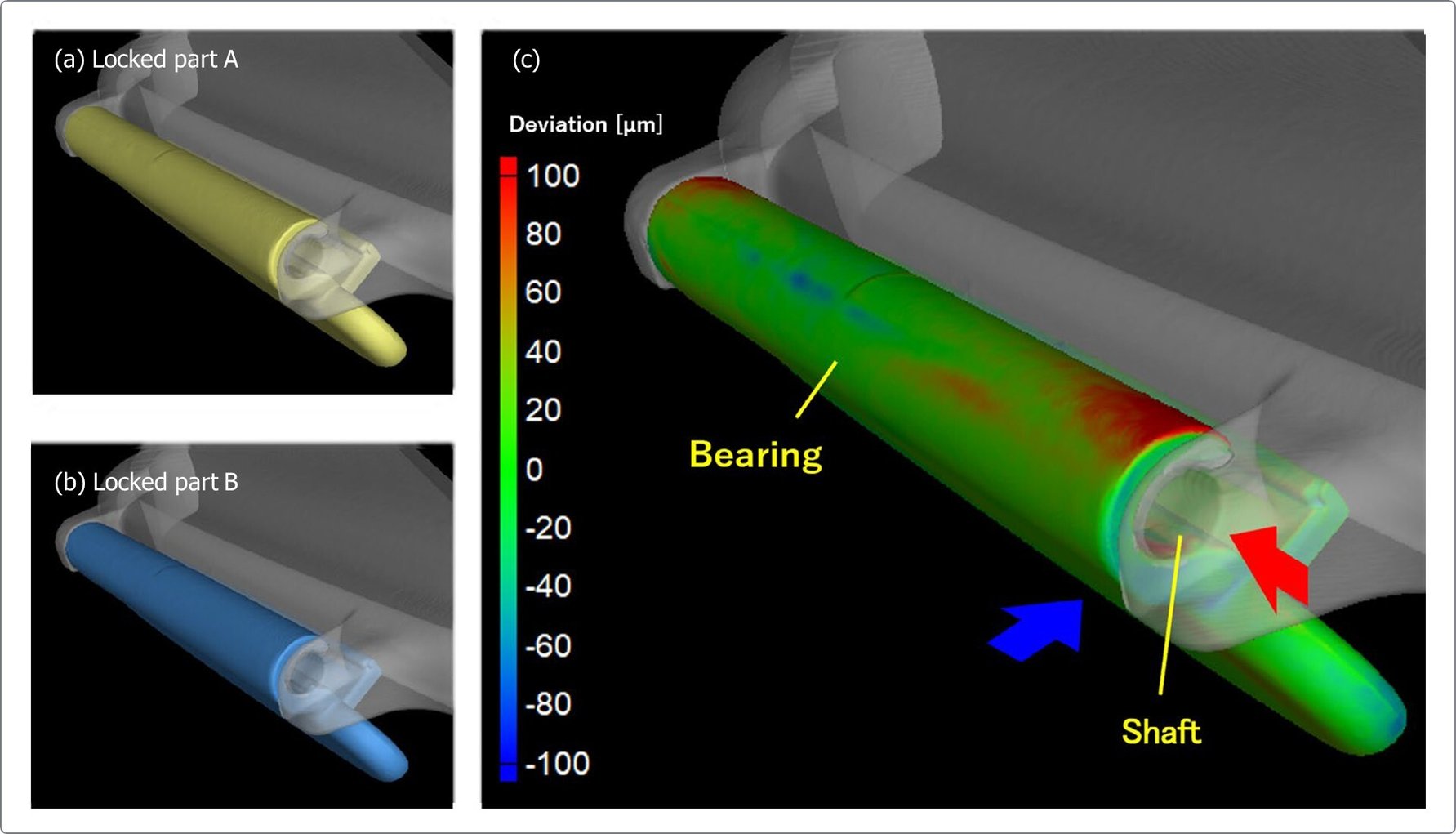

Figure 1: 3D image of locking parts (a) part A, (b) part B and (c) difference coloring of part B against part A

Conclusion

Two different types of lock parts (A: light / B: heavy), each with a different feel when opened and closed, were each CT-imaged for 4 minutes, and the acquired 3D data were superimposed for analysis. The results revealed the existence of a minute shape difference at the bearing end, suggesting that this difference may have an effect on the operating feel (Figure 1(c)). This method can also be used as a decision-making tool for quality improvement, such as design verification and review of molding conditions.