Semi-quantitative Analysis of Glass Raw Materials

Introduction

Since glass is a unique material in that it has both the properties of being physically hard and optically transparent, it is used in an extremely wide range of application from products used in daily life to high-tech fields such as aerospace development. The major component of glass is silica (SiO₂), and other components contained in glass can directly impact its characteristics. For example, Na₂O can lower glasses’ softening temperature, but excessive amount can deteriorate its physical and chemical durability. The amount of ferric oxide (Fe₂O₃) often times contained in the raw glass material can have undesirable effects on the color and clarity. It is therefore important to carefully control the contents of both major and minor compo-nents of the raw glass material in the manufacturing process to attain the desired characteristics in the fin-ished glass product.

X-ray fluorescence (XRF) analysis quickly and easily determines the contents of raw materials and can provide precise elemental analysis results. “SQX” is Rigaku’s semi-quantitative analysis program to obtain concentrations by theoretical calculation using the fundamental parameter (FP) method in combination with the internal sensitivity library. The calculation is performed based on sequential scan measurement results.

This application note demonstrates the performance of the Supermini200 for the semi-quantitative analysis of silica sand and feldspar which are raw glass materials, with easy sample preparation and operation. These natural materials generally have large grain size and mineralogical inhomogeneities, which can degrade the accuracy of semi-quantitative analysis results. To overcome this problem, SQX analysis has a unique “Matching library” function which allows calculating the analysis result using sensitivities matched specifically to the inhomogeneous sample for improved accuracy.

Instrument

The Supermini200 is a benchtop sequential WDXRF spectrometer specifically designed to deliver excellent performance while eliminating conventional installation requirements such as cooling water, special power supply and large floor space. By selecting the optional sealed proportional counter instead of the gas flow proportional counter, requirement of P10 gas can be eliminated as well, realizing a truly utility free WDXRF instrument.

Featuring a unique air-cooled 200W X-ray tube, two detectors, three analyzing crystals and with selectable vacuum or helium environment, the Supermini200 can analyze elements from oxygen to uranium.

The Windows®-based software used to operate the Supermini200 shares the same platform running Rigaku’s popular high-power WDXRF ZSX family instruments. This means that it has the same advanced algorithms, multiple language support and an intuitive user-friendly interface.

Sample Preparation

Loose powder method, which is the easiest in preparing XRF samples, was used in the analysis. 4.0 grams of each sample was poured into a standard sample cup (Chemplex® 1540) with 4.0 μm Prolene® (Chemplex® 416) film. The cups are disposable and inexpensive.

The certified reference materials shown below were used for the SQX analysis.

Feldspar

- GSJ JF-1 (Geological Survey of Japan, AIST)

Silica sand (high and low purity)

- JCRM R401 (The Ceramic Society of Japan)

- JCRM R403 (The Ceramic Society of Japan)

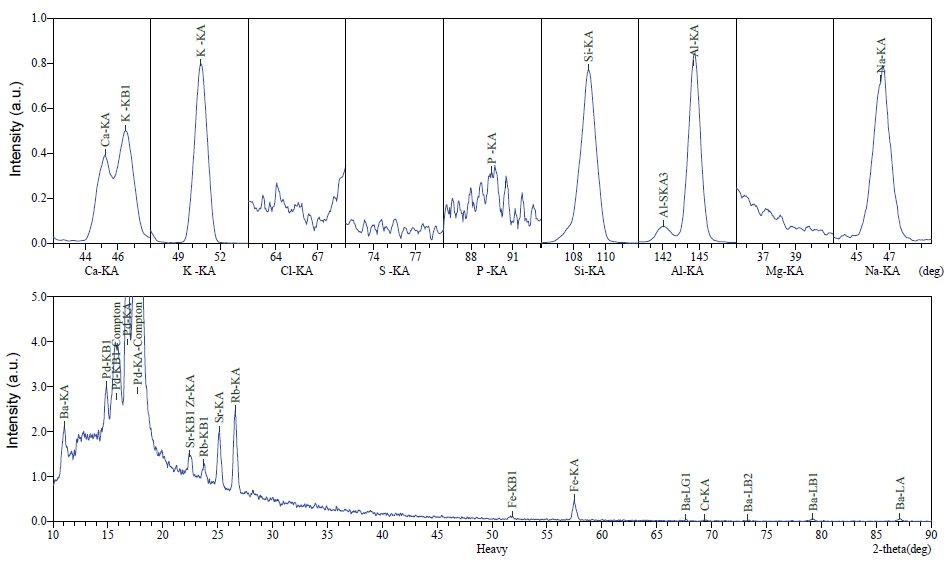

Figure 1: Example of spectral chart (GSJ JF-1)

Measurement

The Supermini200 was used for measurement. Sequential scan measurement from sodium to uranium was performed followed by SQX analysis. The unique fixed angle measurement function was applied to obtain X-ray intensities of Na, Mg, Al, K, Ca, Ti and Fe. After the 2θ scan of the measurement line is completed, by applying the fixed measurement function the instrument re-measures the peak and background X-ray intensities with counting times set by the user. This significantly reduces statistical counting error resulting in improved precision especially for the analysis of trace elements. Since the software automatically chooses the peak and background angles, accurate net intensities are obtained.

The semi-quantitative FP calculation to obtain the analysis result is executed automatically based on the X-ray intensities of the detected elements in the completed sequential scan.

Results

SQX results and reference values are listed in Table 1 and 2. The SQX analysis results are in good agreement with the reference values. Table 1 and 2 compares the results obtained by using only the standard sensitivity library to the Matching library sensitivity added to the standard library. The Matching library is a unique function added to the FP sensitivity library. The function searches a reference sample closest in concentration and sample property to an unknown sample. The SQX analysis results with the Matching library in Table 1 and 2 are much improved for light elements. This is because analysis results of light elements in powder samples generally tend to be more affected by grain size and mineralogical inhomogeneities compared to heavy elements. The Matching library function is effective to improve accuracy by correcting for sample inhomogeneity effects in SQX analysis.

Table 1: Analysis results of feldspar GSJ JF-1

| Component / Element | Certified Value | SQX Value without Matching library | SQX Value with Matching library |

| Na₂O | 3.37 | 3.9 | 3.4 |

| MgO | 0.006 | N.D. | N.D. |

| Al₂O₃ | 18.08 | 19.8 | 18.3 |

| SiO₂ | 66.69 | 64.0 | 66.9 |

| P₂O5 | 0.01 | 0.015 | 0.014 |

| K₂O | 9.99 | 10.9 | 10.0 |

| CaO | 0.93 | 1.0 | 1.0 |

| TiO₂ | 0.005 | 0.008 | 0.005 |

| Cr₂O₃ | - | 0.017 | 0.015 |

| Fe₂O₃ | 0.06 | 0.099 | 0.070 |

| Rb | 0.0266 | 0.032 | 0.026 |

| Sr | 0.0172 | 0.019 | 0.017 |

| Zr | 0.00386 | 0.004 | 0.003 |

| Ba | 0.1750 | 0.20 | 0.18 |

Table 2: Analysis results of silica sand JCRM R401 and R403

| R401 (high purity) | R403 (low purity) | |||||

| Certified Value | SQX Value without Matching library | SQX Value with Matching library | Certified Value | SQX Value without Matching library | SQX Value with Matching library | |

| Na₂O | 0.01 | N.D. | N.D. | 0.33 | 0.45 | 0.33 |

| MgO | - | 0.040 | 0.038 | - | N.D. | N.D. |

| Al₂O₃ | 0.45 | 0.96 | 0.44 | 2.58 | 2.9 | 2.6 |

| SiO₂ | 99.4 | 98.9 | 99.5 | 95.1 | 94.5 | 95.3 |

| SO₃ | - | N.D. | N.D. | - | 0.022 | 0.019 |

| K₂O | <0.01 | 0.012 | 0.009 | 1.5 | 1.8 | 1.5 |

| CaO | - | N.D. | N.D. | - | 0.12 | 0.11 |

| TiO₂ | 0.02 | 0.025 | 0.024 | 0.04 | 0.043 | 0.043 |

| Fe₂O₃ | 0.012 | 0.023 | 0.015 | 0.10 | 0.11 | 0.10 |

| Rb | - | N.D. | N.D. | - | 0.011 | 0.010 |

| Y | - | N.D. | N.D. | - | 0.002 | 0.002 |

| Zr | - | 0.004 | 0.003 | - | 0.021 | 0.018 |

Conclusions

Semi-quantitative analysis by the loose powder method with WDXRF is a technique that can quickly and easily provide chemical compositions of unknown samples. Good analysis results were obtained by making measurement with the Supermini200 equipped with an air-cooled 200 W X-ray tube.

One of the many unique features of the SQX program is the Matching library function. This function can improve accuracy of analysis results and allows versatile screening of mineralogical samples.

Supermini200 is a benchtop spectrometer which is an instrument with a small footprint and is able to be operated with only a wall power outlet. Since Supermini200 is not site-specific, it has the great advantage that it can be installed anywhere, and is therefore particularly suited for mining sites of small laboratories.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.