Analysis of Aqueous Liquids with Internal Standard

Introduction

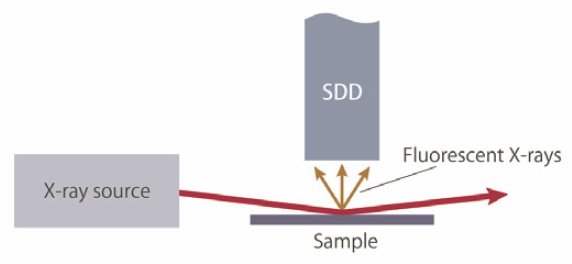

An incident X-ray beam impinges upon the sample at a shallow angle resulting in virtually complete reflection of the excitation beam away from the silicon drift detector (Figure1). This affords dramatically reduced background contributions in the measured energy dispersive X-ray fluorescence spectra. Ultratrace elemental analysis of the liquid sample becomes possible using the NANOHUNTER II and “Drop and Dry” sample preparation technique.

Figure 1: TXRF principle

Measurement and results

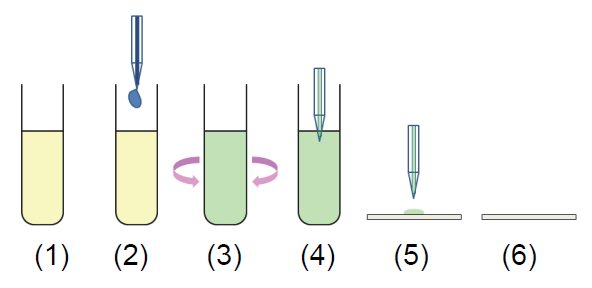

The quantitative analysis for commercial aqueous standard sample was carried out with internal standard method. The protocol of the internal standard method is shown in Figure 2.

- Measure out a sample

- Add internal standard

- Mix well

- Collect few µL aliquot

- Drop onto a reflector

- Dry

In general, the internal standard element is selected from one which is not contained in the sample. The internal standard sample was prepared with 10ppm of Ga in this measurement.

Figure 2: Procedure of internal standard method

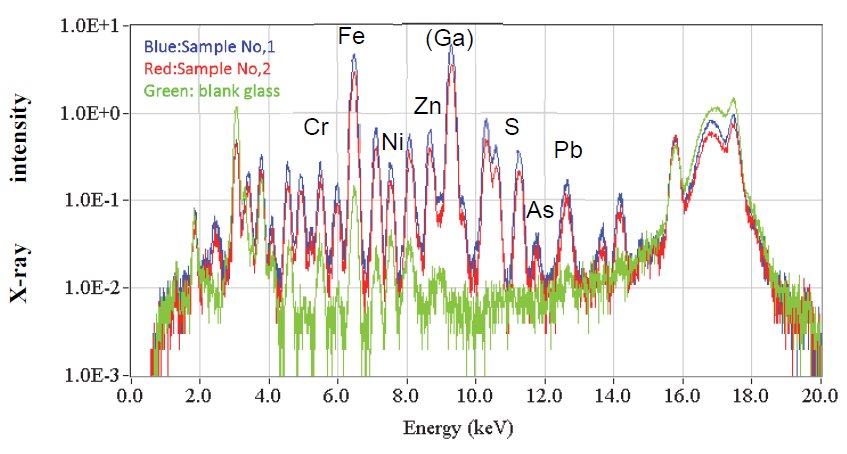

The spectra of the dropped and dried liquid sample measurements are shown in Figure 3. The results with excellent reproducibility of measurement were obtained. The quantitation of elements for the internal standard was carried out using relative sensitivity. The result shows good agreement with the standard values.

It is easily possible to measure trace elements in the aqueous samples using internal standard method. The environmental analysis such as effluent and impurity test of the beverages are suitable application of this method.

Figure 3: Spectra of treated solution samples

Table 1: Quantitative analysis result (ppm)

| Element | Standard value | +Ga 10 ppm No. 1 |

+Ga 10 ppm No. 2 |

| Fe | 15.3 | 16.5 | 17.4 |

| Cr | 1.0 | 1.25 | 1.29 |

| Cu | 1.0 | 1.08 | 1.11 |

| Zn | 1.0 | 1.07 | 1.06 |

| Ni | 0.5 | 0.60 | 0.63 |

| Pb | 0.5 | 0.28 | 0.30 |

| Se | 0.5 | 0.49 | 0.48 |

| Mn | 0.4 | 0.45 | 0.46 |

| As | 0.3 | 0.41 | 0.31 |

| Ga | – | 10.0 | 10.0 |

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.