Unique Variable-angle GI-XRF Capability

Introduction

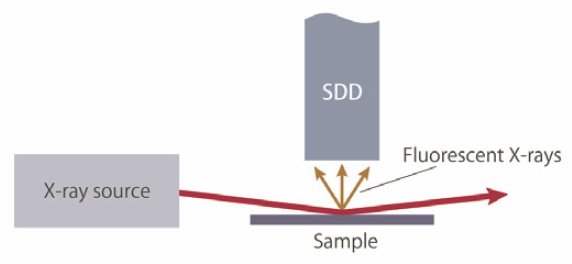

An incident X-ray beam impinges upon the sample at a shallow angle resulting in virtually complete reflection of the excitation beam away from the silicon drift detector (Figure 1). This affords dramatically reduced background contributions in the measured energy dispersive X-ray fluorescence spectra. Furthermore, it is possible to obtain information depending on measuring depth with GI-XRF capability.

Figure 1: TXRF principle

Measurement and results

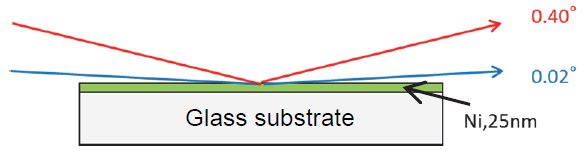

In this example, a 25 nm nickel (Ni) thin film on a glass substrate was measured at two different incident angles: 0.02° and 0.40° (Figure 2). The results of the measurement are shown in Figure 3. Incident angle 0.02° is under condition of TXRF and then only the surface information is obtained. On the other hand, angle 0.40° is higher than the critical angle then it is possible to measure deeper area beneath the surface.

Figure 2: Nickel coated sample

Only Ni was strongly excited at 0.02° GI (Grazing Incidence) excitation condition (blue spectrum). However, elements included in the glass substrate are strongly exited at the higher 0.40° angle (red spectrum) because X-rays penetrate more deeply into the substrate. It is possible to change incident angle arbitrarily, and then the characterization of the solid surface can be done by using this function.

%20for%20differenct%20incident%20angles.jpg?width=1039&height=555&name=B-XRF3003%20Figure%203%20Spectra%20of%20the%20Ni%20thin%20film%20(25%20nm)%20for%20differenct%20incident%20angles.jpg) Figure 3: Spectra of the Ni thin film (25 nm) for different incident angles

Figure 3: Spectra of the Ni thin film (25 nm) for different incident angles

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.