Observation of Orientation State of Polypropylene Film Products by 2D-GI-WAXS Measurement

Introduction

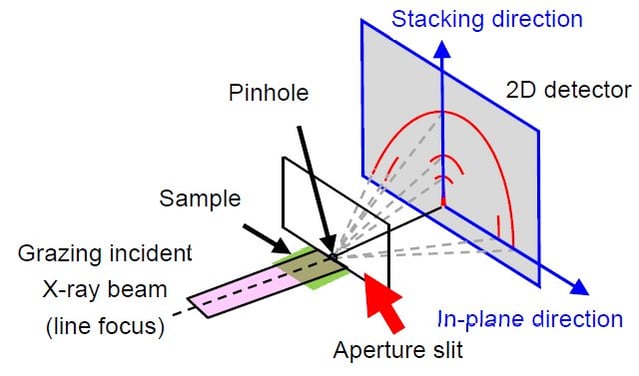

The grazing-incidence wide-angle X-ray scattering (GI-WAXS) technique is often employed for the measurement of ultrathin film specimens since their very weak signals can be effectively observed. GI-WAXS can be applied to materials that cannot be evaluated by transmission WAXS, such as thin film on a substrate or a polymer film with metal deposition on the back surface. The combination of a 2D-SAXS/WAXS attachment with an aperture slit and a 2D detector allows the acquisition of clearly resolved 2D diffracted images by a general X-ray diffractometer with a line-shaped incident beam (Figure 1).

Measurements and results

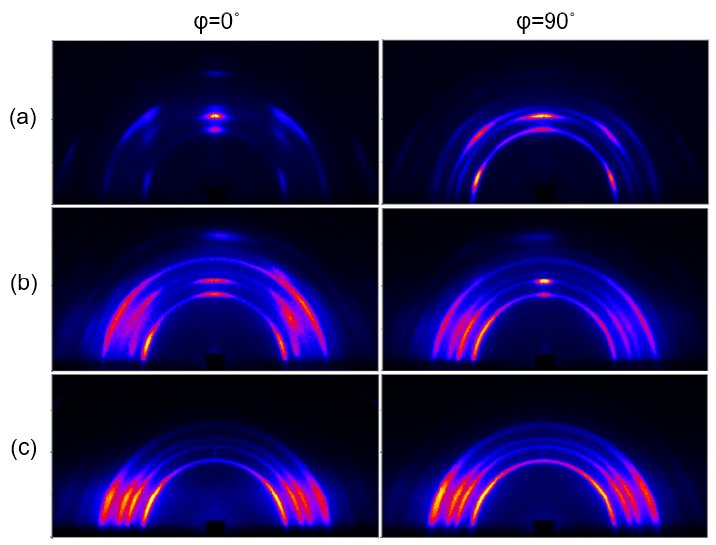

GI-WAXS images of a polypropylene packing tape, snack package, and liquid seasoning pouch were observed by a 2D detector. Figure 2 shows the resulting 2D-GI-WAXS images, with a 65 mm camera length (observed 2θ range: 0-30˚), a 0.2˚ incident angle, and a 60 sec. exposure time. Figure 2(a) shows discontinuous Debye rings and different images between two sample setting directions (φ = 0˚ and 90˚). This indicates that the packing tape has quite a high degree of crystal orientation. In contrast, Figure 2(b) and (c) show relatively continuous Debye rings and little difference between sample setting directions. This suggests those samples do not have a high degree of crystal orientation.

Figure 1: GI-WAXS geometry with a 2D detector.

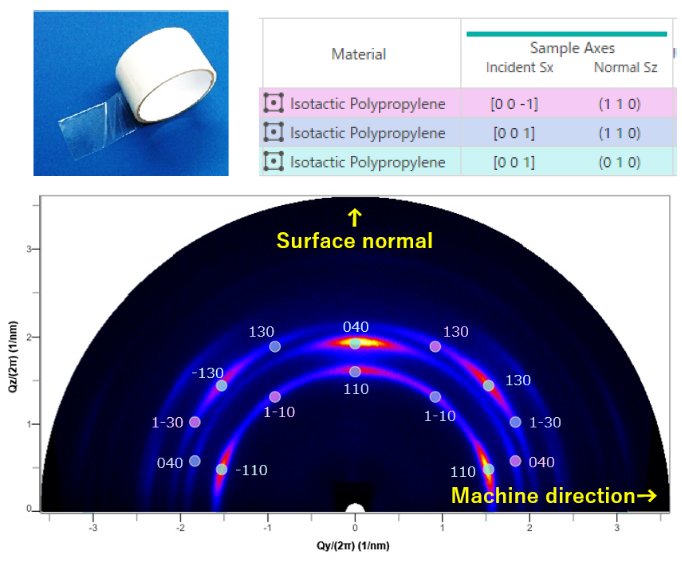

By comparing a GI-WAXS image to a reciprocal lattice simulation, it is possible to discuss the crystal orientation condition in detail. Figure 3 shows the 2D-GI-WAXS image of the packing tape (Fig. 2(a), φ=90°) transformed to a Q-coordinate plot and the simulated reciprocal lattice points. The ● marks in the figure show the simulated positions of reciprocal lattice points, whose crystal structure factor F are large. Since the simulated positions of the reciprocal lattice points showed good agreement with the measurement data, it indicates that the c-axis of polypropylene was aligned along the machine direction of the packing tape.

Figure 2: 2D-GI-WAXS images of (a) a packing tape, (b) snack package, and (c) seasoning pouch.

Figure 3: Q-coordinate plot and assignment of each reciprocal lattice point of the packing tape.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.