Observation of Butter Crystal by Simultaneous XRD-DSC Measurement

Introduction

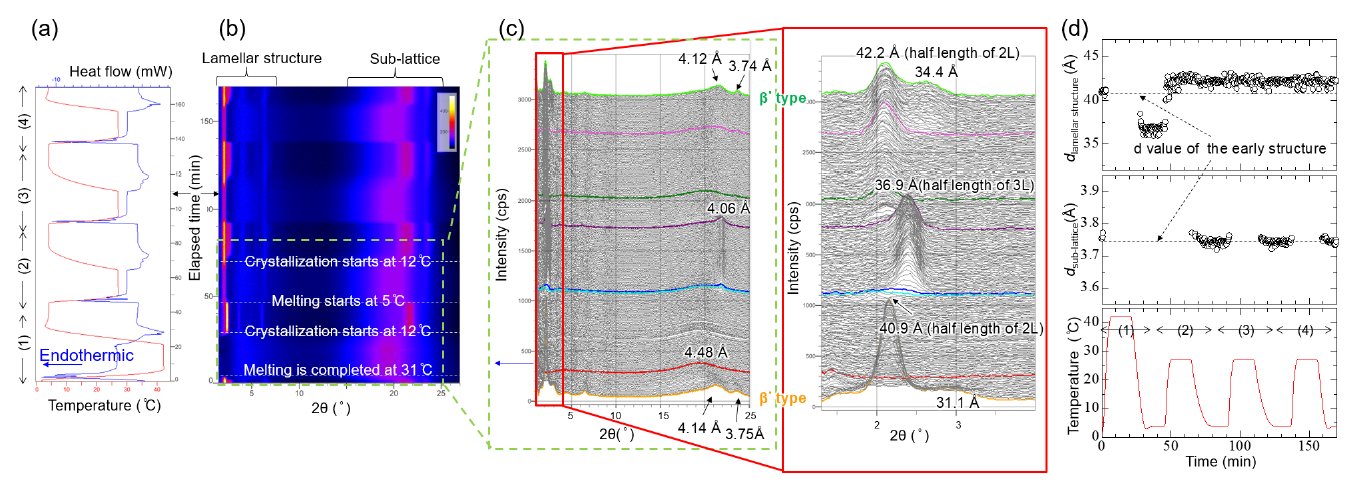

The taste and texture of butter are vulnerable to temperature change. Many researchers in the food industry point out that control of the lamellar structure and the sublattice structure of butter crystal is needed in order to produce butter with rich taste regardless of the storage temperature. Simultaneous X-ray diffraction and DSC measurement (XRD-DSC) facilitates the determination of the onset temperature at which crystallization and melting begin, and the identification of the crystal structure. Here, temperature changes of the lamellar and sub-lattice structures, which affect the taste and texture of butter, are investigated by XRD-DSC measurements.

Measurements and results

Figure 1 shows the XRD-DSC results. A 2D camera was used for the observation of the lamella and the sub-lattice structure under the same temperature conditions. The temperature profile modeled the process from the purchase of butter to home use in summer. After heating to 40°C, it was cooled down to 5°C (1cycle, (1)); heating and cooling in the temperature range of 5-30°C were repeated three times. The DSC curve showed an endothermic reaction as soon as heating began, and the butter was completely melted at 31°C. Crystallization starts at 12°C when cooled, and melts from 5°C when heated again. The lamella structure and the sub-lattice structure crystallized after the melting process are different from those in the initial crystal structure. When cooled again (2cycle, (2)), the sub-lattice structure showed the original orthorhombic crystal structure of β' type. However, the lamellar structure shows a longer periodicity of 2 Å compared to the initial structure even after the second cooling. These results suggest that changes in the length of the periodicity in the lamella structure may affect taste and texture. In addition, it indicates that the initial structure can be reproduced through a tempering process that deliberately changes the crystallization temperature. Simultaneous measurement of DSC, which detects subtle changes of heat flow at an early stage of crystallization and the melting, and X-ray diffraction, which identifies the crystal structure, is indispensable to investigate the tempering conditions.

Figure 1: Result of simultaneous XRD-DSC measurement of butter. (a) Temperature and heat flow chat, (b) Time-dependent change in diffraction intensity of the 2θ-I profile converted from the 2D data, (c) Diffraction profile changes and the enlarged view of diffraction peaks related to the lamellar structure, (d) d-value changes of lamellar and sub-lattice structure.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.