Zirconium on Aluminum

Scope

The measurement of zirconium (Zr) conversion coating on aluminum is demonstrated.

Background

Aluminum and steel are often coated with a protective conversion coating, also called passivate or passivation coating, to prevent oxidation and corrosion of the base metal. Conversion coatings include chromium (Cr), titanium (Ti), vanadium (V), manganese (Mn), nickel (Ni), or zirconium (Zr). A phosphate coating may be applied as well to minimize wear on cutting tools and stamping machines. Aluminum is often coated for use in aircraft parts, aluminum window frames and other similar industries where the aluminum is exposed to weathering. Steel for the automotive industry is typically first galvanized with a zinc coating before the conversion coating is applied. Protected steel is also used for outdoor sheds and other similar uses where steel is exposed to weathering. Conversion coatings also help in the retention of paint for the final finished product.

_picture_2020.06.25.jpg?width=800&height=610&name=800x610%20NEX%20QC%2B%20(S%20in%20Crude%20screen)_picture_2020.06.25.jpg) Model: NEX QC

Model: NEX QC

Calibration

An empirical calibration was built using a set of standards assayed by careful weigh-strip-weigh.

| Element: Zr Units: mg/ft² |

||

| Sample I.D. | Standard value | Calculated value |

| STD 1 | 0.98 | 1.150 |

| STD 2 | 2.21 | 2.227 |

| STD 3 | 3.52 | 3.484 |

| STD 4 | 4.81 | 4.679 |

| STD 5 | 6.71 | 6.618 |

| STD 6 | 15.26 | 15.333 |

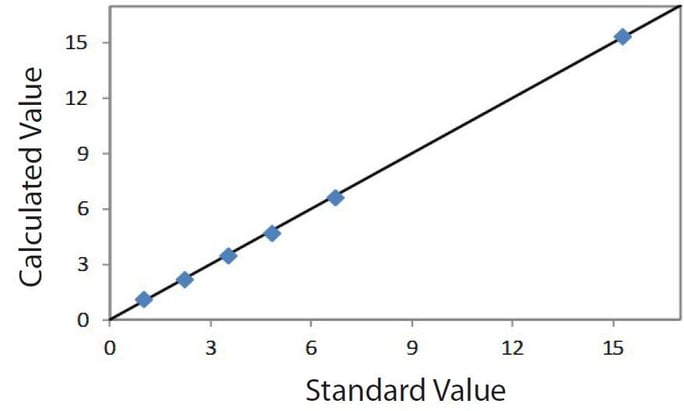

Correlation plot Zr on aluminum

Correlation plot Zr on aluminum

Recovery and repeatability

To demonstrate repeatability (precision), three calibration standards were chosen. Each sample was measured in a static position for ten repeat analyses with typical results shown below.

| Element: Zr Units: mg/ft² |

||||

| Sample I.D. | Standard value | Average value | Std. dev | % Relative |

| STD 1 | 0.98 | 1.165 | 0.056 | 5.7 |

| STD 4 | 4.81 | 4.707 | 0.050 | 1.0 |

| STD 6 | 15.26 | 15.193 | 0.077 | 0.5 |

Sample surface and positioning

Aluminum may be surfaced with different patterns to give products various esthetic looks or physical properties. Such surfacing techniques may leave the aluminum smooth, may be brushed aluminum with a directional grain pattern, or may be a hatched or other pattern. The samples demonstrated here had a brushed, directional grain pattern.

Conclusion

The performance shown here demonstrates NEX QC provides excellent sensitivity and performance for the measuring zirconium conversion coatings on aluminum.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.