Gold Processing

Scope

On-line analysis of gold in impregnated stripping solutions during the electrowinning process is demonstrated.

Background

Gold ore processors commonly utilize the cyanide leaching technique to recover trace gold content. After the gold is leached out of the ore, it is typically absorbed onto activated carbon in processes such as Carbon-in-Pulp (CIP), Carbon-in-Leach (CIL), or Carbon Column (CC). Once absorbed, the gold is stripped from the carbon and the impregnated stripping solution fed into the electrowinning process where the gold is recovered by electrolysis. By measuring the gold in the stripping solution real-time, operations can trend when the solution will be barren of gold, significantly improving the plant’s efficiency.

The Rigaku NEX OL offers a simple and low maintenance on-line analytical technique for trending such solutions. Results are communicated to your plant DCS (distributed control system) via 4 – 20 mA current loops or MODBUS® over Ethernet connection allowing for real time closed loop control.

Model: NEX OL

Model: NEX OL

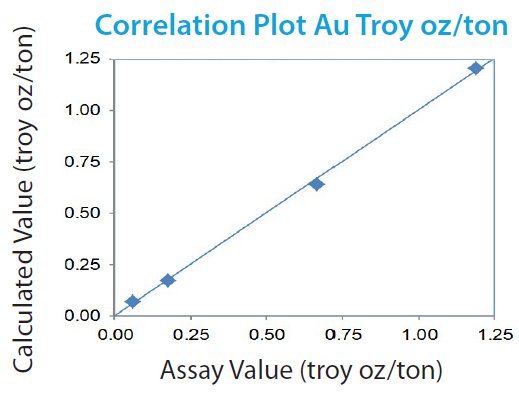

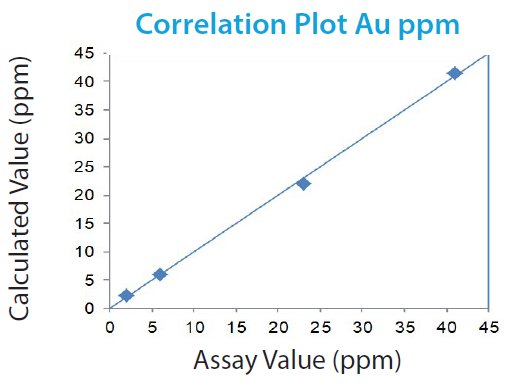

Calibration

A simple linear empirical calibration was built using a suite of four calibration standards assayed by AA. Calibration can be made in units of ppm or troy oz/ton.

| Element: Au | ||

| Units: troy oz/ton | ||

| Sample I.D. | Assay value | Calculated value |

| 2 | 0.058 | 0.067 |

| 6 | 0.174 | 0.174 |

| 23 | 0.667 | 0.638 |

| 41 | 1.189 | 1.204 |

| Element: Au | ||

| Units: ppm | ||

| Sample I.D. | Assay value | Calculated value |

| 2 | 2.0 | 2.3 |

| 6 | 6.0 | 6.0 |

| 23 | 23.0 | 22.0 |

| 41 | 41.0 | 41.5 |

Precision

Instrument repeatability (precision) is determined by ten repeat analyses of a sample in static position. Precision results are summarized here.

| Element: Au Units: troy oz/ton | |||

| Sample | Standard value | Average value | Std. dev |

| 6 | 0.174 | 0.145 | 0.012 |

| 23 | 0.667 | 0.632 | 0.020 |

| Element: Au Units: ppm | |||

| Sample | Standard value | Average value | Std. dev |

| 6 | 6.0 | 5.0 | 0.4 |

| 23 | 23.0 | 21.8 | 0.7 |

NEX OL features and benefits

Real-time process control

Real-time process control- Trend analysis charting

- 50 kV X-ray tube excitation source with high resolution and count rate silicon drift detector (SDD) technology

- Industrial touchscreen user interface

- Unique toolless flow cell design

- 4 – 20 mA or MODBUS® over Ethernet results reporting

Conclusion

The NEX OL offers real-time trend analysis in a simple yet powerful and versatile system for quantifying the elemental composition of a process stream. The results of this study indicate that given stable samples, proper sample handling and proper calibration technique, the Rigaku NEX OL EDXRF can achieve excellent results in monitoring the concentration of gold strip solutions as part of the electrowinning process.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.