RoHS PE by Empirical Method

Scope

The measurement of Cr, Hg, Pb, Br and Cd in polyethylene (PE) is demonstrated for RoHS rapid screening by XRF.

Background

The Restriction on Hazardous Substances (RoHS) initiative limits the allowable amounts of the toxic elements chromium, mercury, lead, bromine, and cadmium in plastics and consumer goods. Energy dispersive X-ray fluorescence (EDXRF) is an accepted analysis technique for the rapid screening by XRF and quantification of the hazardous element according to RoHS norms. To meet the industry needs, Rigaku offers the NEX DE VS analyzer with automatic collimators and a camera for sample positioning and sample image, giving QA/QC technicians the means for fast and simple screening and analysis of materials that must conform to RoHS and similar directives.

Model: NEX DE VS

Model: NEX DE VS

Calibration

Empirical calibration was performed using the thin certified standards available from Sumika Chemical Services, Ltd. and thick certified standards from ASI Standards. An automatic correction was used to compensate for variations in sample thickness. In this way, separate methods or user input is not required for the measurement of samples having different thicknesses.

Calibration validation

10 repeat measurements of ASI Standards QC check sample were measured to validate the calibration.

| 10 mm Collimator Units: ppm |

|||

| Element | Standard value | Average value | Std. dev |

| Cr | 500 | 545 | 1.0 |

| Hg | 500 | 445 | 1.0 |

| Pb | 500 | 502 | 1.5 |

| Br | 250 | 254 | 0.6 |

| Cd | 50 | 57 | 0.5 |

| 3 mm Collimator Units: ppm |

|||

| Element | Standard value | Average value | Std. dev |

| Cr | 500 | 536 | 1.2 |

| Hg | 500 | 435 | 1.4 |

| Pb | 500 | 497 | 1.6 |

| Br | 250 | 252 | 1.2 |

| Cd | 50 | 57 | 1.1 |

| 1 mm Collimator Units: ppm |

|||

| Element | Standard value | Average value | Std. dev |

| Cr | 500 | 529 | 4.7 |

| Hg | 500 | 446 | 4.0 |

| Pb | 500 | 501 | 8.8 |

| Br | 250 | 261 | 4.2 |

| Cd | 50 | 54 | 5.9 |

Sensitivity validation

10 repeat measurements of ERM-680 k were measured to validate sensitivity at low levels.

| 10 mm Collimator Units: ppm |

|||

| Element | Standard value | Average value | Std. dev |

| Cr | 20 | 22 | 0.5 |

| Hg | 5 | 11 | 0.2 |

| Pb | 14 | 12 | 0.3 |

| Br | 96 | 92 | 0.4 |

| Cd | 20 | 19 | 0.4 |

| 3 mm Collimator Units: ppm |

|||

| Element | Standard value | Average value | Std. dev |

| Cr | 20 | 22 | 0.6 |

| Hg | 5 | 9 | 0.3 |

| Pb | 14 | 8 | 0.4 |

| Br | 96 | 90 | 0.5 |

| Cd | 20 | 19 | 0.9 |

| 1 mm Collimator Units: ppm |

|||

| Element | Standard value | Average value | Std. dev |

| Cr | 20 | 31 | 1.6 |

| Hg | 5 | 9 | 0.8 |

| Pb | 14 | 12 | 0.9 |

| Br | 96 | 89 | 0.7 |

| Cd | 20 | 22 | 2.7 |

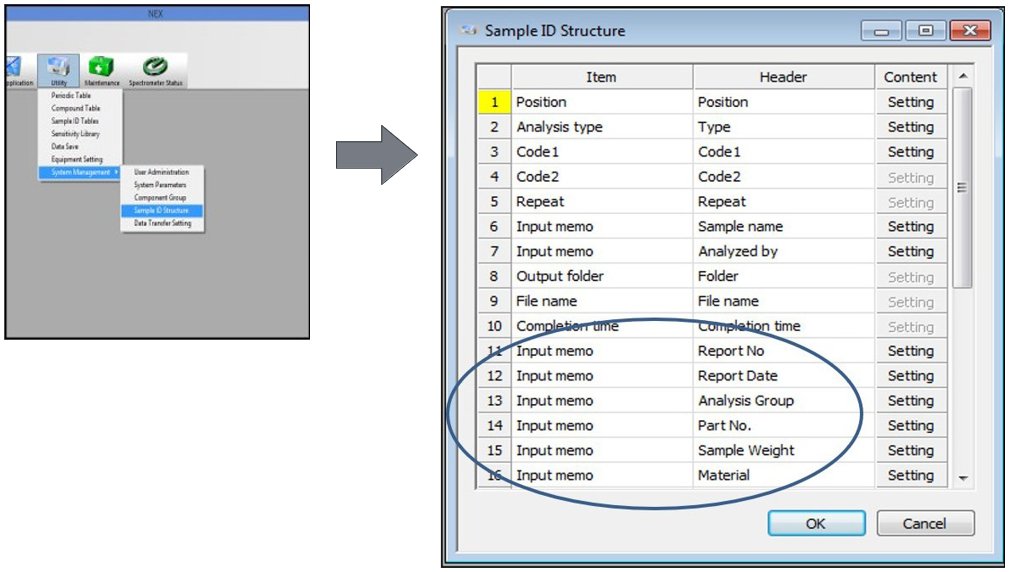

User-definable RoHS report fields

The flexible Rigaku software allows users to design RoHS report field headers to suit specific reporting needs. Headers to report Sample Name and Analyzed By are automatically set by default, and the user simply enters up to six additional report memo headers as desired.

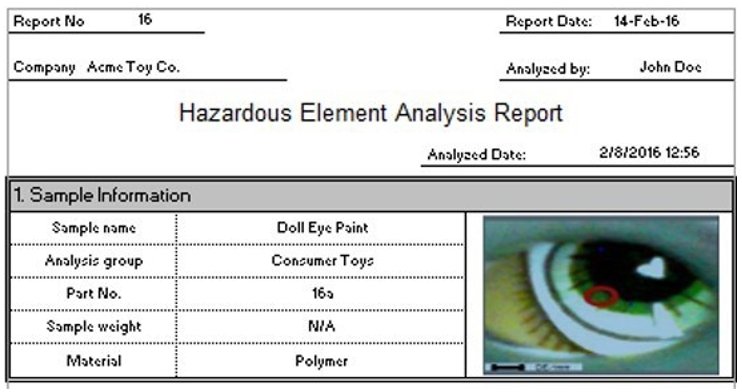

RoHS report

A RoHS report is automatically generated that includes the user defined fields, sample image, and element judgment.

Conclusion

Conclusion

The NEX DE VS with automatic collimators and camera provides excellent sensitivity and reliable precision for RoHS rapid screening by XRF down to 1 mm spot size. Simple Point Analysis Screen allows operators to easily enter report information as designed using customizable report headers and automatically generates a RoHS report complete with sample image, analysis results, and Pass/Unsure/Fail judgment.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.