Chemical Bath for Copper Foil Surface Treatment

Scope

Measurement of aqueous chemical bath solutions containing nickel, cobalt, molybdenum, zinc, and indium is demonstrated.

Background

Surface treating is an important part of the manufacturing of copper foil for the electronics industry. Surface treatments are used to clean the copper foil, to create roughing and heat resistance treatments, and to make single or multiple layer thin film coatings to prevent oxidation or enhance the electro-chemical properties of the copper foil. The chemical baths must be constantly monitored to ensure the highest quality surface treatments. Rigaku offers the NEX OL analyzer to meet these analytical needs for trend analysis of bath composition.

Model: NEX OL

Model: NEX OL

Calibration

Empirical calibrations were developed using aqueous samples. A summary of typical calibration is shown here.

| Component | Concentration range (ppm) |

| Zn | 750 – 1425 |

| In | 140 – 320 |

| Ni | 4500 – 5500 |

| Mo | 780 – 1525 |

| Co | 1275 – 1750 |

Sample recovery and precision

A representative mid-concentration standard was selected and analyzed against the empirical calibrations to demonstrate effective recovery and precision. The sample was analyzed 10 consecutive times in a static position. Typical performance results are provided below.

Sample ID: Zn-In-Std3 / Units: ppm

| Element | Assay value | NEX OL value* | Std. dev value* | RSD(%) |

| Zn | 1100 | 1118 | 16 | 1.5 |

| In | 220 | 222 | 3 | 1.2 |

* NEX OL value reflects the averge of the 10 repeat analysis

Sample ID: NMC Std3 / Units: ppm

| Element | Assay value | NEX OL value* | Std. dev value* | RSD(%) |

| Ni | 5200 | 5362 | 36 | 0.7 |

| Mo | 1100 | 1115 | 4 | 0.4 |

| Co | 1500 | 1547 | 19 | 1.3 |

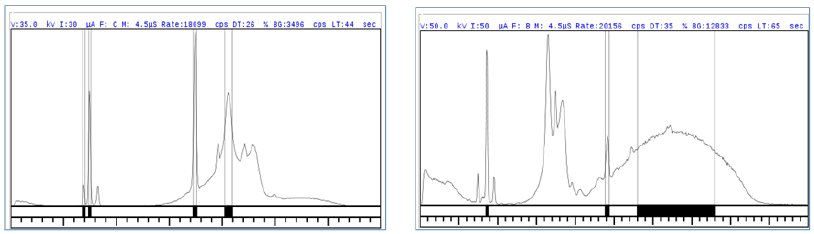

Multi-element analysis

The Rigaku NEX OL system uses a high-resolution semiconductor detector that achieves excellent resolution and sensitivity. Adjacent or near-adjacent elements can be measured with little or no peak overlap, as shown in these typical spectra.

NEX OL features and benefits

Real-time process control

Real-time process control- Trend analysis charting

- Capable of measuring elements Al to U, depending on application

- Robust Rigaku NEX QC+ optical kernel with SDD detector

- Industrial touchscreen user interface

- Unique toolless flow cell design

Conclusion

The NEX OL offers high-throughput manufacturers a simple yet powerful and versatile system for quantifying the elemental composition of their process stream. The results of this study indicate that given stable samples, proper sample handling, and proper calibration technique, the Rigaku NEX OL EDXRF can achieve excellent results in monitoring the concentration of chemical solutions used in the manufacturing of copper foil.