Chlorine and Sulfur in Cement

Scope

Scope

The analysis of chlorine (Cl) and sulfur (as SO₃) in cement is demonstrated.

Background

Monitoring proper levels of chlorine is especially vital in producing cement. Soluble chlorine, most often CaCl₂, can be added to concretes and cements as an accelerating agent for faster strength development or shorter setting times. However, the presence of chlorine in reinforced concrete can cause corrosion of the steel reinforcing material, possibly causing premature structural damage. Sulfur in cement is often monitored during the addition of gypsum to the mixtures. The sulfur content in part determines drying rates and strength, as well as the ability of the cement to dry under water. For these reasons it is vital to monitor and control both the chlorine and sulfur levels. To meet this analytical need, Applied Rigaku Technologies offers a small, simple to use, benchtop EDXRF system ideal for use along the production and QC processes in a cement plant.

_picture_2020.06.25.jpg?width=800&height=610&name=800x610%20NEX%20QC%2B%20(S%20in%20Crude%20screen)_picture_2020.06.25.jpg) Model: NEX QC

Model: NEX QC

Calibration

Nine assayed cement samples were used to develop empirical calibrations for Cl and SO₃. The results of the calibrations are reported below. Mg, Al, Si, K, Ca, Fe, and Sr were also measured, without the need to have assay values. It is important to measure the elements present in the cement mix to enable alpha correction that compensate for matrix effects due to variations in X-ray absorption/enhancement effects. To model the sample set shown here, only two alpha corrections were required for the Cl and SO₃ fits. Different cement mixtures and calibration sets may require different sets of alpha corrections.

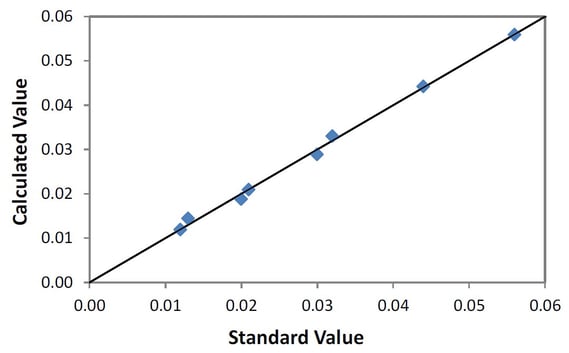

Cl calibration

| Element: Cl Units: % |

||

| Sample I.D. | Standard value | Calculated value |

| 1 | 0.020 | 0.0188 |

| 2 | 0.012 | 0.0119 |

| 3 | 0.013 | 0.0144 |

| 5 | 0.044 | 0.0442 |

| 6 | 0.030 | 0.0289 |

| 7 | 0.021 | 0.0209 |

| 8 | 0.032 | 0.0330 |

| 9 | 0.056 | 0.0559 |

Correlation plot Cl

Correlation plot Cl

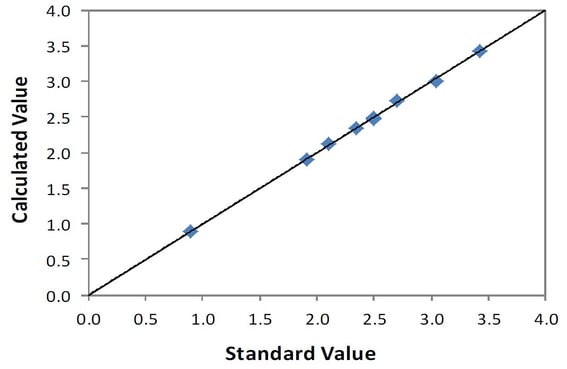

SO₃ calibration

| Element: SO₃ Units: % |

||

| Sample I.D. | Standard value | Calculated value |

| 1 | 2.34 | 2.348 |

| 2 | 2.10 | 2.125 |

| 3 | 1.91 | 1.894 |

| 4 | 0.89 | 0.895 |

| 5 | 3.42 | 3.434 |

| 6 | 2.70 | 2.730 |

| 7 | 2.50 | 2.489 |

| 8 | 3.04 | 3.012 |

| 9 | 2.50 | 2.474 |

Correlation plot SO₃

Correlation plot SO₃

Repeatability

To demonstrate recovery and repeatability (precision), two calibration standards were selected. Each was measured in 10 repeat analyses without moving the sample between measurements.

| Sample ID: 2 Units: % |

|||

| Element | STD value | NEX QC value | STD dev |

| Cl | 0.012 | 0.0104 | 0.0006 |

| SO₃ | 2.10 | 2.089 | 0.027 |

| Sample ID: 9 Units: % |

|||

| Element | STD value | NEX QC value | STD dev |

| Cl | 0.056 | 0.0526 | 0.0009 |

| SO₃ | 2.50 | 2.540 | 0.025 |

Conclusion

The results show NEX QC provides excellent performance for the measurement of Cl and SO₃ in cement using matrix-matched standards to model the particular clinker or cement type. The NEX QC offers a simple and fast means of analysis during the QA/QC process in the production of cement.