Lead Analysis in Gasoline — ASTM D5059-21 — using WDXRF ZSX Primus IV𝒾

Introduction

Lead (Pb), in the form of alkyl lead such as tetraethyl lead, used to be added to gasoline as an antiknock additive to increase the octane rating. However, alkyl lead is highly poisonous. Gasoline with alkyl lead, called leaded gasoline, causes air pollution. Nowadays, most countries, except in Africa, ban leaded gasoline for vehicles. Alkyl lead is still used as an additive in aviation gasoline.

Although lead-free gasoline, called unleaded gasoline, is common in most countries, lead occurs as a contaminant—either unintentionally or intentionally—in some countries. Therefore, it is necessary to check the lead concentration in gasoline.

This application note demonstrates quantitative analysis of low concentration lead in gasoline according to ASTM D5059-21 on Rigaku ZSX Primus IVi, a wavelength dispersive X-ray fluorescence (WDXRF) spectrometer.

Instrument

The ZSX Primus IVi, a tube-below sequential WDXRF spectrometer, is optimized for the routine analysis that today’s petroleum laboratories need to perform. The programmable, switchable vacuum seal between the sample and optical chambers can keep the optical chamber under vacuum with the sample chamber under helium, and, therefore, minimize helium gas consumption and time of atmosphere change in the sample chamber. The spectrometer is equipped with a 4 kW or 3 kW X-ray tube and analyzing crystals covering O to Cm in the standard configuration.

The system software is designed for ease of use in routine analyses. The Flowbar in quantitative analysis guides users in establishing calibration. The Sample ID Table and the Program Operation help operators carry out daily analysis.

Measurements were performed on the ZSX Primus IVi with a 4 kW X-ray tube operating at 50 kV and 40 mA using a LiF(200) analyzing crystal and the S2 slit included in the standard configuration. Primary beam filter Al125, inserted between the sample and the X-ray tube, protects the X-ray tube window against damage from falling samples during measurement and also improves peak-to-background ratio.

Analysis method of ASTM D5059-21

The analysis demonstrated in this application note followed Method C of ASTM D5059-21, for low concentration lead, 0.01 g Pb / US gal – 0.5 g Pb / US gal (0.0026 g / L – 0.13 g / L).

In Method C of ASTM D5059-21, the internal standard method with bismuth (Bi) is employed. For each solution of calibration standards or analysis gasoline samples, exactly 20 mL is taken and 2 mL of the Bi internal standard solution (3.00 g Bi / US gal) is added and mixed thoroughly.

X-ray intensities of the following three lines are measured:

- Pb-Lα (at 1.175 Å)

- Bi-Lα (at 1.144 Å)

- Background (1.194 Å)

The intensity ratio R is determined by the following formula:

R = ( A - C ) / B

where A: counting rate at 1.175 Å (Pb-Lα)

B: counting rate at 1.144 Å (Bi-Lα)

C: counting rate at 1.194 Å (background).

The corrected ratio RC is determined as follows:

RC = R - Rb

where Rb: ratio (R) for blank.

A calibration curve is made with RC and the slope S of the resulting line is determined as follows:

S = (g Pb / US gal) / RC .

The lead content of analysis samples is calculated as follows:

Pb content (g / US gal) = S x RC.

The obtained values of the lead content are reported to the nearest 0.005 g / US gal.

Calibration and standards

"Standards for Lead in Gasoline" (isooctane base), which consists of 0.000 (blank), 0.001, 0.005, 0.010, 0.050, 0.100 and 0.300 g Pb / US gal, and "Internal Standards for XRF Analysis; Bi 0.793 g / L" provided by VHG Labs (LGC Standards) were used to make a calibration curve.

For each calibration standard, exactly 20 mL was taken and 2 mL of the Bi internal standard was added and mixed thoroughly. Approximately 6 g of the mixture of each calibration standard and the Bi internal standard was poured into the liquid cell, Chemplex XRF Sample Cups 1095, with 6.0 μm polyester film.

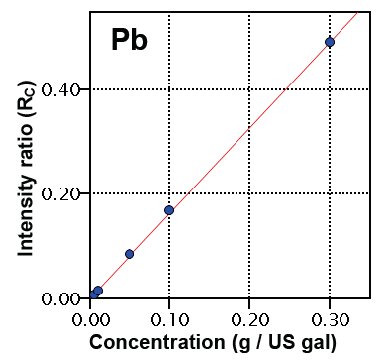

The X-ray intensities of Pb-Lα, Bi-Lα and the background (1.194 Å) were measured for each of the calibration standards. The counting time was 20 seconds for each line. Then, RC was calculated and the calibration curve was made. The obtained calibration curve was shown in Figure 1.

Figure 1: Calibration curve of lead (Pb) in gasoline by bismuth (Bi) internal standard. The accuracy of calibration is 0.0016 g / US gal.

The accuracy of calibration was calculated by the following formula:

$Accuracy = \sqrt{ \frac{\sum_i{(C_i-\hat{C}_i)^2}}{n-m} }$

$C_i$: certified value of standard sample

$\hat{C}_i$: calculated value of standard sample

n : number of standard samples.

m: degree of freedom (2: linear)

Repeatability test

For repeatability tests, solutions with approximately 0.01 g Pb / US gal and 0.05 g Pb / US gal were prepared by mixing an organometallic standard of Pb with isooctane 75% - toluene 25%.

Repeatability tests were carried out for the above two solutions (~0.01 g Pb / US gal and ~0.05 g Pb / US gal). For the same sample, two aliquots were prepared and quantified with the calibration; this process was repeated twenty times. The test results are tabulated in Table 1, in which the average and the difference of two aliquots each are shown and r represents "repeatability" defined in ASTM D5059-21, which states that the difference between successive test results obtained by the same operator with the same apparatus under constant operation conditions on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following values only in one case in twenty:

r = 0.007 + 0.14 X

X: g Pb/US gal.

The test results shown in Table 1, where the difference between two aliquots does not exceed the repeatability (r), prove that the performance of the ZSX Primus IVi meets the requirement of ASTM D5059-21.

Another test by 10-time measurements was carried out using the same solutions. Ten aliquots were prepared and measured consecutively. The results of the 10-time measurement are tabulated in Table 2.

Table 1: Result of repeatability test for ASTM D5059-21.

| Sample: ~0.01 g Pb / US gal | (unit: g Pb / US gal) | ||||

| Run | 1st aliq. | 2nd aliq. | Average | Diff. | r (limit) |

| 01 | 0.005 | 0.010 | 0.008 | 0.005 | 0.008 |

| 02 | 0.010 | 0.010 | 0.010 | 0.000 | 0.008 |

| 03 | 0.010 | 0.010 | 0.010 | 0.000 | 0.008 |

| 04 | 0.010 | 0.010 | 0.010 | 0.000 | 0.008 |

| 05 | 0.010 | 0.005 | 0.008 | 0.005 | 0.008 |

| 06 | 0.005 | 0.005 | 0.005 | 0.000 | 0.008 |

| 07 | 0.010 | 0.005 | 0.008 | 0.005 | 0.008 |

| 08 | 0.010 | 0.010 | 0.010 | 0.000 | 0.008 |

| 09 | 0.010 | 0.010 | 0.010 | 0.000 | 0.008 |

| 10 | 0.010 | 0.010 | 0.010 | 0.000 | 0.008 |

| 11 | 0.010 | 0.010 | 0.010 | 0.000 | 0.008 |

| 12 | 0.010 | 0.010 | 0.010 | 0.000 | 0.008 |

| 13 | 0.010 | 0.005 | 0.008 | 0.005 | 0.008 |

| 14 | 0.005 | 0.010 | 0.008 | 0.005 | 0.008 |

| 15 | 0.010 | 0.010 | 0.010 | 0.000 | 0.008 |

| 16 | 0.005 | 0.010 | 0.008 | 0.005 | 0.008 |

| 17 | 0.005 | 0.010 | 0.008 | 0.005 | 0.008 |

| 18 | 0.010 | 0.005 | 0.008 | 0.005 | 0.008 |

| 19 | 0.005 | 0.005 | 0.005 | 0.000 | 0.008 |

| 20 | 0.005 | 0.010 | 0.008 | 0.005 | 0.008 |

| Sample: ~0.05 g Pb / US gal | (unit: g Pb / US gal) | ||||

| Run | 1st aliq. | 2nd aliq. | Average | Diff. | r (limit) |

| 01 | 0.040 | 0.045 | 0.043 | 0.005 | 0.013 |

| 02 | 0.045 | 0.045 | 0.045 | 0.000 | 0.013 |

| 03 | 0.045 | 0.040 | 0.043 | 0.005 | 0.013 |

| 04 | 0.040 | 0.040 | 0.040 | 0.000 | 0.013 |

| 05 | 0.040 | 0.040 | 0.040 | 0.000 | 0.013 |

| 06 | 0.045 | 0.040 | 0.043 | 0.005 | 0.013 |

| 07 | 0.045 | 0.045 | 0.045 | 0.000 | 0.013 |

| 08 | 0.045 | 0.045 | 0.045 | 0.000 | 0.013 |

| 09 | 0.045 | 0.045 | 0.045 | 0.000 | 0.013 |

| 10 | 0.045 | 0.045 | 0.045 | 0.000 | 0.013 |

| 11 | 0.045 | 0.045 | 0.045 | 0.000 | 0.013 |

| 12 | 0.045 | 0.045 | 0.045 | 0.000 | 0.013 |

| 13 | 0.045 | 0.045 | 0.045 | 0.000 | 0.013 |

| 14 | 0.045 | 0.040 | 0.043 | 0.005 | 0.013 |

| 15 | 0.040 | 0.040 | 0.040 | 0.000 | 0.013 |

| 16 | 0.040 | 0.040 | 0.040 | 0.000 | 0.013 |

| 17 | 0.040 | 0.045 | 0.043 | 0.005 | 0.013 |

| 18 | 0.045 | 0.045 | 0.045 | 0.000 | 0.013 |

| 19 | 0.045 | 0.045 | 0.045 | 0.000 | 0.013 |

| 20 | 0.045 | 0.045 | 0.045 | 0.000 | 0.013 |

Table 2: Repeatability test results by 10-time measurement.

| Sample | ~0.01 g Pb / US gal | ~0.05 g Pb / US gal |

| Run | g Pb / US gal | g Pb / US gal |

| 01 | 0.005 | 0.040 |

| 02 | 0.005 | 0.045 |

| 03 | 0.010 | 0.045 |

| 04 | 0.010 | 0.045 |

| 05 | 0.010 | 0.045 |

| 06 | 0.010 | 0.045 |

| 07 | 0.010 | 0.045 |

| 08 | 0.010 | 0.045 |

| 09 | 0.005 | 0.045 |

| 10 | 0.010 | 0.040 |

| Average | 0.009 | 0.044 |

| (0.0024 g / L) | (0.0116 g / L) | |

| Std. Dev. | 0.0024 | 0.0021 |

| (0.0006 g / L) | (0.0006 g / L) |

Conclusion

Lead in gasoline can be routinely analyzed with high accuracy and precision on the ZSX Primus IVi, a sequential WDXRF spectrometer. This application note demonstrates that the performance of the ZSX Primus IVi meets the requirement of ASTM D5059-21.

Reference

ASTM 5059-21 Standard Test Methods for Lead in Gasoline by X-Ray Spectroscopy

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.