Analysis of S, Fe, Ni and V in Residual Oil According to IP610/13

Scope

This App Note demonstrates the capabilities of the Rigaku NEX CG EDXRF analyzer for the measurement of thin film thickness (Tox) applied to semiconductor wafers. Simple 2-point empirical calibrations are used for SiO₂, AlSi, Ti, TiN, Pt, AlCu, and BPSG single layer films on silicon substrates for use in quality control in the semiconductor industry.

Background

Process control in semiconductor manufacturing is critical. Tight tolerances leave little margin for error in the processing of semiconductor materials. Film thickness and concentration integrities are vital to optimal device performance. Semiconductor processing involves the sequential deposition of multiple layers to complete the device. Any errors during the construction of these devices can lead to undesirable effects in future processing and lead to device failure or degradation.

Process control in semiconductor manufacturing is critical. Tight tolerances leave little margin for error in the processing of semiconductor materials. Film thickness and concentration integrities are vital to optimal device performance. Semiconductor processing involves the sequential deposition of multiple layers to complete the device. Any errors during the construction of these devices can lead to undesirable effects in future processing and lead to device failure or degradation.

Model: NEX CG

Model: NEX CG

Calibration and measurement

All single layer films were deposited on silicon monitor wafers with 1000 Å of SiO₂ (used as an adhesion layer). To demonstrate the performance of NEX CG a series of six different 2-point calibrations were developed for the thickness of the films AlCu, AlSi, Pt, Ti, and TiN. BPSG composition was determined by measuring P, and the B:P ratio was constant at 1:1. In each calibration a 1000 Å SiO₂ film deposited on silicon was used as the zero point or blank sample. The second point in each calibration was obtained from the calibration standard of interest. A 1-point calibration was developed for the SiO₂ film. Single point or two point calibrations can be used for thin film thickness analysis since the X-ray response is linear at low thickness ranges. As thickness increases the XRF response is curved. For example, the AlSi layer thickness is curved over the range 0-10000 Å, and to fully characterize the entire range at least four calibrations are required.

Recovery

Following calibration, all calibration standards were analyzed to demonstrate valid recovery. Results are listed below:

| Tox Data Units: Å |

|||

| Sample Film | Standard value | Average value* | % Difference |

| AlCu | 9581.6 | 9539.5 | 0.4% |

| AlSi | 11689.8 | 11845.1 | -1.3% |

| Pt | 990.3 | 982.4 | 0.8% |

| Ti | 1004.8 | 1004.9 | 0.0% |

| TiN | 997.6 | 993.2 | 0.4% |

| SiO2 | 1000.0 | 1025.5 | -2.6% |

* Average value reflects the calculated value from the calibration.

| P Concentration Data Units: Mass % |

|||

| Sample film | Standard value | Average value* | % Difference |

| BPSG** | 4.0 | 4.1 | -2.5% |

** The ratio of B to P is at a fixed ratio of 1:1

Repeatability

Representative samples were analyzed to determine measurement repeatability (precision). Ten repeat analyses were performed in a static position.

| Tox Data Units: Å |

|||

| Sample Film | Standard value* | Average value | Standard deviation |

| AlCu | 10087.8 | 10185.3 | 29.0 |

| AlSi | 8275 | 8279.2 | 48.9 |

| Pt | 1000 | 1058.3 | 2.1 |

| Ti | 1000 | 986.0 | 1.9 |

| TiN | 1005 | 1006.2 | 2.3 |

* Nominal values supplied with the samples.

| P Concentration Data Units: Mass % |

|||

| Sample film | Standard value* | Average value | Standard deviation |

| BPSG** | 4 | 4.2 | 0.1 |

** The ratio of B to P is at a fixed ratio of 1:1

Qualitative analysis

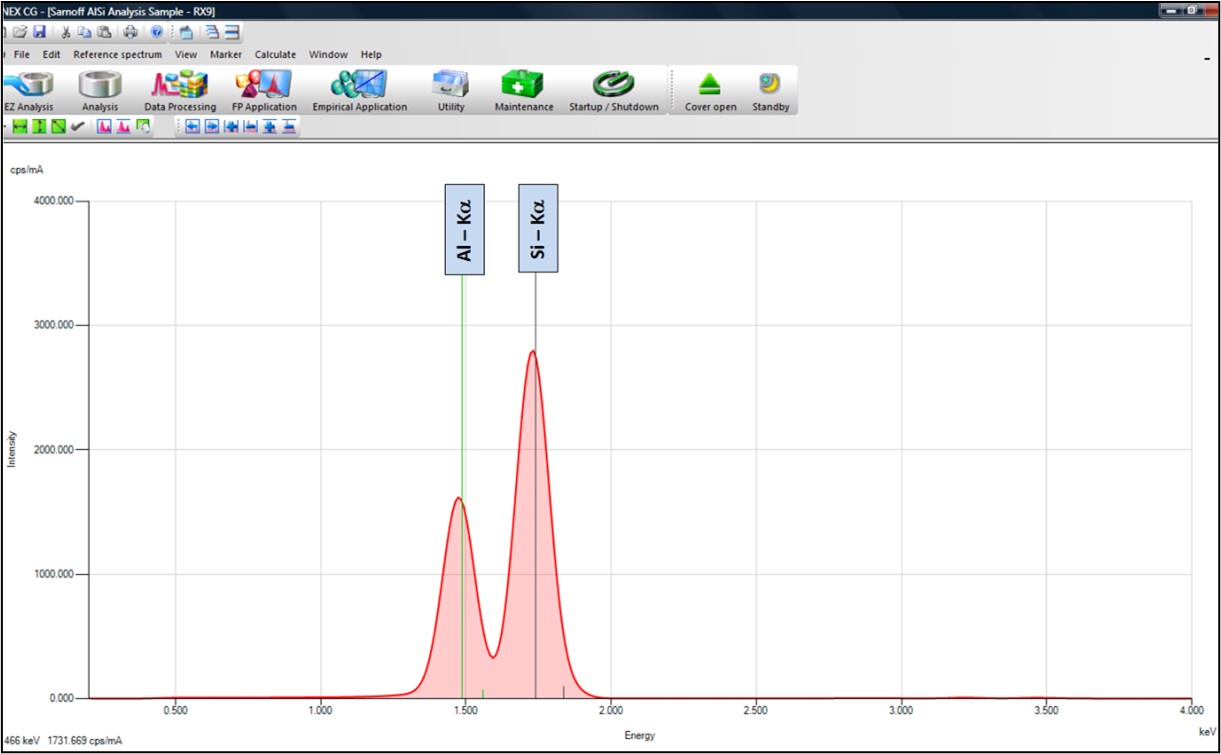

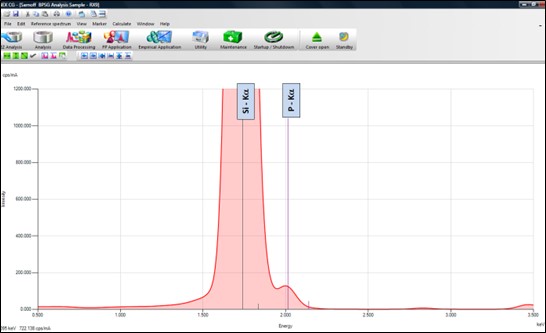

Excellent peak resolution is observed for each element. Example spectra using the RX9 polarization target are provided below to demonstrate superior light element measurement.

AlSi film using RX9 Polarization Target

AlSi film using RX9 Polarization Target BPSG film on RX9 Secondary Target

BPSG film on RX9 Secondary Target

Discussion

The NEX CG offers the value and flexibility to be used as a monitoring tool throughout the semiconductor process cycle. The NEX CG can provide routine monitoring for dopant concentration (CVD and Diffusion), thickness uniformity (CMP), etch rate (Wet and Dry Etch), and absolute thickness (Metallization) processes. The NEX CG can also be used to identify trace contaminants that could potentially lead to device failure.

Conclusion

The NEX CG offers analysts a simple yet powerful and versatile system for indentifying and quantifying elemental composition. The results of this study indicate the Rigaku NEX CG EDXRF analyzer with indirect excitation and polarization is an excellent tool for screening and quantifying thickness, concentration, and trace contaminants for semiconductor processing materials. The NEX CG can reliably measure elements from Na to U and this versatility will allow the NEX CG to adapt as existing processes are refined and new processes are introduced.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.