Textile and Fiber Industry using the nano3DX

Introduction

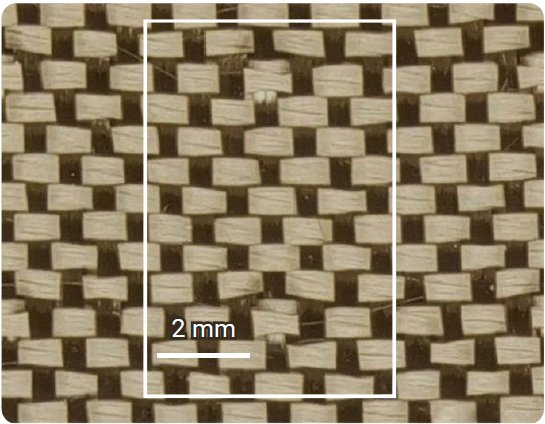

The Rigaku nano3DX was utilized to study a basalt two-layer fabric in which two fabrics were woven together and connected by a bond at a constant distance of 10 mm. The main aim was to analyze the behavior of the threads around the bonds. Both submicron and large field of view (vertical and horizontal stitching) CT measurements were demonstrated.

Instrument

The nano3DX is a true X-ray microscope (XRM) with the ability to measure relatively large samples at very high resolution. This is accomplished by using a high-powered rotating anode X-ray source and a high-resolution sCMOS X-ray camera. The rotating anode provides for fast data acquisition and the ability to switch anode materials easily to optimize the data acquisition.

Figure 1: Fabric sample–with labeled region of interest (ROI) for large FOV measurement. Made by the Faculty of Textile Engineering. (Department of Technologies and Structures, Technical University of Liberec, Czech Republic)

Sample preparation

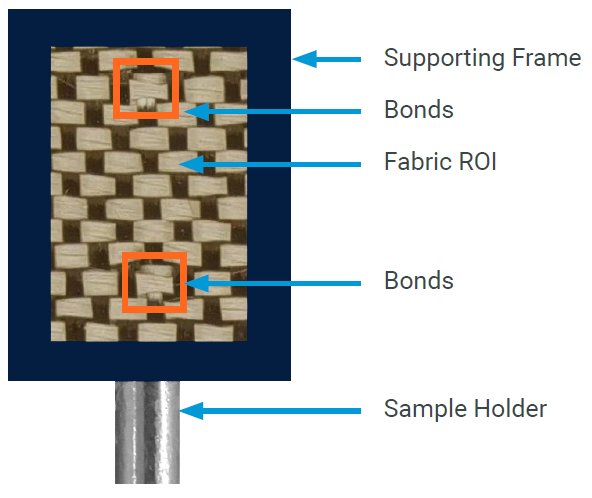

The selected region of the fabric was attached, while stretched, to a supporting frame made from kapton plate and cut out. The structure was then fixed to a sample holder.

Figure 2: Sample preparation for large FOV CT measurement.

Measurement

To cover the large sample area of 5 mm x 10 mm (W x H), the stitching strategy was utilized to enlarge the FOV in the vertical direction. Two consecutive measurements, with defined Z-stage movement between them, were done using a low-magnification optical lens unit. To study the sample with submicron spatial resolution, another measurement of the selected ROI was done using the highest magnification lens unit.

| Sample | Target material | Voxel size [μm] | FOV [mm] | Measurement time [hh:mm] |

| Fabric (Large FOV*) |

Mo | 4.13 | 7.2 x 5.6 | 2:30 |

| Fabric (Detail) |

Mo | 0.53 | 0.9 x 0.7 | 7:30 |

* Parameters for one measurement.

CT data and results

The acquired CT data were further processed to improve data quality by noise reduction and contrast enhancement. The resulting high quality enabled the study of a complex morphology around bonds. Specifically, in the case of the submicron CT data, it was possible to visualize bonds among individual threads and to analyze the behavior of the threads around the bonds of the analyzed intertwined fabric. The results show, that the threads around the bonds are longer, enabling better mechanical properties like ductility of the fabric.

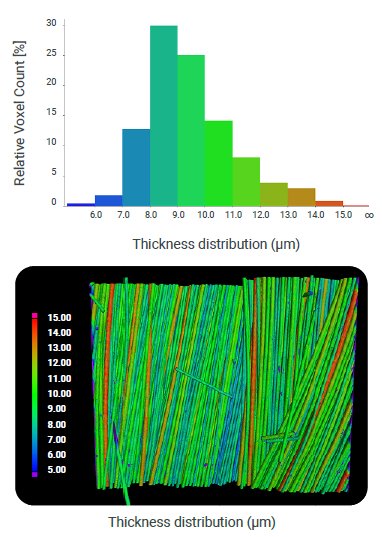

Additional information can be obtained from the high-quality nano3DX CT data, such as fiber orientation and distribution and corresponding thickness distribution of the fibers inside the investigated sample.

Figure 3: Results of fiber orientation analyses and thickness distribution of the investigated sample.

Fabric (Large FOV)

.jpg?width=796&height=440&name=XCT2101%20Fabric%20(Large%20FOV).jpg)

Fabric (Detail)

.jpg?width=822&height=434&name=XCT2101%20Fabric%20(detail).jpg)

CT analysis performed by CEITEC – CT Lab

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.