Analysis of Low-concentration Sulfur in Petroleum-based Fuels by Benchtop WDXRF according to ASTM D2622-16

Introduction

Sulfur in petroleum-based fuels contributes to atmospheric pollution. Sulfur content in fuels, especially in automobile fuels, is strictly controlled and regulations of sulfur content in fuel oil, such as diesel fuel and gasoline, have been tightened. Therefore, control of sulfur content is very important in refineries. X-ray fluorescence (XRF) spectrometry has been used for quantitative analysis of sulfur in petroleum-based fuels, owing to simple sample preparation. In XRF analysis of fuel oil, the sample is simply poured into a plastic cup equipped with a transparent film without any complicated treatment, such as chemical decomposition or serial dilution. In addition, concentration of total sulfur is obtained in XRF analysis.

This application note demonstrates quantitative analysis of low concentration sulfur in diesel fuel, gasoline and kerosene according to ASTM D2622-16 on Rigaku Supermini200, a benchtop wavelength-dispersive X-ray fluorescence (WDXRF) spectrometer.

Instrument

The Supermini200 is a benchtop sequential WDXRF spectrometer designed specifically to deliver excellent performance while eliminating typical installation requirements, such as cooling water, special power supply, large floor space, etc.

Featuring a unique air-cooled 200 W X-ray tube, two detectors, programmable environment of vacuum or helium, and three analyzing crystals, the Supermini200 can analyze elements from fluorine to uranium.

The Windows-based software running the Supermini200 is shared with Rigaku’s popular Primus family of higher-power WDXRF systems, which means that it has the same advanced algorithms, multiple language support and an intuitive user-friendly interface.

Measurements were performed on the Supermini200 using a PET analyzing crystal, included in the standard crystals, with the X-ray tube operating at 50 kV and 4.0 mA. The counting time was 300 seconds for peak and 150 seconds for background.

Sample preparation

Four milliliters of each sample was poured into a standard liquid cell (Chemplex® 1540) equipped with 3.6 μm Mylar® (Chemplex® 150).

Standard and sample preparation

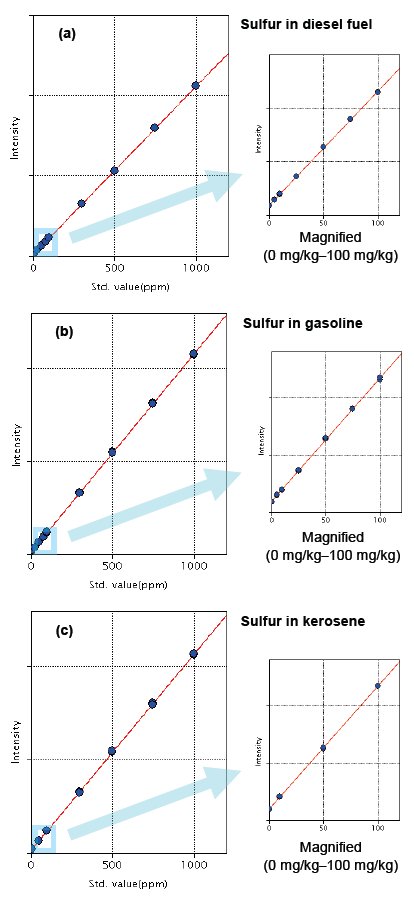

“Number 2 diesel fuel” standards, isooctane-based standards and kerosene-based standards provided by VHG Labs were used for calibration of diesel fuel, gasoline and kerosene respectively. The calibration curves are shown in Figure 1 and the calibration results are listed in Table 1.

Figure 1: Calibration curve for each material (a) Diesel fuel; (b) Gasoline; (c) Kerosene

Table 1: Calibration result for each material (in mg/kg)

| Material | Diesel fuel | Gasoline | Kerosene |

| Calibration range | 0 – 1000 | 0 – 1000 | 0 – 1000 |

| Accuracy | 3.2 | 2.0 | 3.3 |

| LLD | 0.5 | ||

The accuracy of calibration was calculated by the following formula:

$Accuracy = \sqrt{ \frac{\sum_i{(C_i-\hat{C}_i)^2}}{n-m} }$

$C_i$: calculated value of standard sample

$\hat{C}_i$: reference value of standard sample

n : number of standard samples.

m: degree of freedom (linear 2, quad. 3)

The lower limit of detection (mg/kg) was calculated by the following formula:

$LLD = 3 \cdot \frac{1}{m} \cdot \sigma_B = 3 \cdot \frac{1}{m} \cdot \sqrt{\frac{I_B}{1000 \cdot t}}$

$m$ : sensitivity of calibration (kcps/mass%)

$\sigma_B$ : standard deviation of blank intensity (kcps)

$I_B$ : blank intensity (kcps)

$t$ : counting time (s); 100 s is used

Analysis results

In order to assess the repeatability of the method, two aliquots of a representative sample were prepared and quantified with the calibration; this process was repeated twenty times.

The test data are compiled in Table 2 (a) for diesel fuel, Table 2 (b) for gasoline and Table 2 (c) for kerosene, which show the average and the difference of the results of each two-aliquot measurement. ASTM D2622-16 defines “repeatability (r)” by

Repeatability (r) = 0.1462·X0.8015 mg/kg [1]

X: total sulfur concentration (mg/kg)

and states that the difference between successive test results obtained by the same operator with the same apparatus under constant operation conditions on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the values calculated by Equation [1] only in one case in twenty.

For diesel fuel and gasoline, other repeatabilities, which are not mandatory, are provided in Appendix of ASTM D2622-16.

Diesel fuel: r = 0.1037 X0.8000 (mg/kg)

Gasoline: r = 0.5006 X0.4377 (mg/kg)

X: total sulfur concentration (mg/kg)

These values for the test are also shown in Table 2 (a) and Table 2 (b) for reference.

Table 2: Repeatability test result (qualification test for ASTM D2622-16)

(a) Diesel fuel

| Run # | Average (mg/kg) | Difference (mg/kg) |

| 1 | 9.5 | 0.4 |

| 2 | 10.0 | 0.3 |

| 3 | 9.6 | 0.1 |

| 4 | 9.7 | 0.6 |

| 5 | 9.1 | 0.7 |

| 6 | 9.8 | 0.1 |

| 7 | 9.9 | 0.3 |

| 8 | 9.6 | 0.2 |

| 9 | 9.8 | 0.2 |

| 10 | 9.5 | 0.3 |

| 11 | 9.8 | 0.5 |

| 12 | 9.3 | 0.4 |

| 13 | 9.7 | 0.1 |

| 14 | 9.8 | 0.1 |

| 15 | 9.6 | 0.1 |

| 16 | 9.8 | 0.0 |

| 17 | 9.8 | 0.1 |

| 18 | 9.9 | 0.2 |

| 19 | 9.8 | 0.4 |

| 20 | 10.2 | 0.5 |

| Avg. 10.2 | ||

| Maximum | 0.7 | |

| r (repeatability)* | 0.9 |

(b) Gasoline

| Run # | Average (mg/kg) | Difference (mg/kg) |

| 1 | 9.2 | 0.1 |

| 2 | 9.2 | 0.1 |

| 3 | 9.3 | 0.5 |

| 4 | 9.9 | 0.0 |

| 5 | 9.8 | 0.8 |

| 6 | 9.0 | 0.5 |

| 7 | 9.5 | 0.1 |

| 8 | 9.6 | 0.2 |

| 9 | 9.8 | 0.0 |

| 10 | 9.8 | 0.1 |

| 11 | 9.9 | 0.5 |

| 12 | 9.4 | 0.2 |

| 13 | 9.2 | 0.2 |

| 14 | 9.0 | 0.2 |

| 15 | 9.2 | 0.5 |

| 16 | 8.7 | 0.4 |

| 17 | 9.2 | 0.1 |

| 18 | 9.3 | 0.0 |

| 19 | 9.3 | 0.1 |

| 20 | 9.4 | 0.1 |

| Avg. 9.4 | ||

| Maximum | 0.8 | |

| r (repeatability)* | 0.9 | |

| r in Appendix** | 0.6 |

(c) Kerosene

| Run # | Average (mg/kg) | Difference (mg/kg) |

| 1 | 9.2 | 0.3 |

| 2 | 9.5 | 0.3 |

| 3 | 9.8 | 0.7 |

| 4 | 9.2 | 0.4 |

| 5 | 9.6 | 0.1 |

| 6 | 9.6 | 0.2 |

| 7 | 9.5 | 0.5 |

| 8 | 9.0 | 0.5 |

| 9 | 9.5 | 0.0 |

| 10 | 9.5 | 0.5 |

| 11 | 9.1 | 0.8 |

| 12 | 9.9 | 0.6 |

| 13 | 9.3 | 0.2 |

| 14 | 9.4 | 0.2 |

| 15 | 9.2 | 0.6 |

| 16 | 9.8 | 0.2 |

| 17 | 9.6 | 0.7 |

| 18 | 10.3 | 0.3 |

| 19 | 10.0 | 0.6 |

| 20 | 9.4 | 0.1 |

| Avg. | 9.5 | |

| Maximum | 0.8 | |

| r (repeatability)* | 0.9 | |

| r in Appendix** | 1.3 |

** This “r” is defined in Appendix of ASTM D2622-16 and is not mandatory for qualification.

The test results shown in Table 2, where the difference of two aliquots does not exceed the repeatability (r) for each material, prove that the performance of the Supermini200 easily satisfies the requirement of ASTM D2622-16 for diesel fuel, gasoline and kerosene.

Conclusion

This application note desmonstrates that low concentration sulfur in petroleum-based fuel can be routinely analyzed with excellent accuracy, sensitivity and repeatability using a benchtop WDXRF spectrometer with minimal site requirements.

In particular, the Rigaku Supermini200 benchtop WDXRF system, which does not require external water for cooling an X-ray tube or special power supply, meets the specification of ASTM D2622-16, which has become more stringent in the recent versions of ASTM D2622.

Reference

ASTM D2622-16, Standard Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry, ASTM International, (2016), 12pp.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.