Cement Raw Meal Analysis by the Pressed Powder Method

Introduction

Cement is one of the most important materials for construction. Various physical properties are given to cement by changing the mineral composition of clinker; therefore, it is important to control the chemical composition of cement raw meal.

XRF spectrometry has been used for chemical composition analysis in cement production processes owing to its simple sample preparation, rapid analysis and high precision.

This application note demonstrates quantitative analysis for cement raw meal by the pressed powder method on Rigaku ZSX Primus III+, a sequential wavelength dispersive XRF spectrometer.

Instrument

The ZSX Primus III+, a tube-above sequential wavelength dispersive X-ray fluorescence (WDXRF) spectrometer, is optimized for routine analyses in powder sample analysis.

The tube-above optics, the programmable vacuum speed and the powder trap of the ZSX Primus III+ enable secure analysis of powder samples and low frequency of maintenance by preventing pressed pellet samples from breaking and falling and by protecting the vacuum pump and magnetic valves from fine particles scattered from samples.

The ZSX Primus III+ has a pre-evacuation chamber. A sample is evacuated in this chamber and then the sample is transported into the measurement position. During the measurement, the next sample to be analyzed can be loaded into the pre-evacuation chamber during the measurement cycle of the current sample, which reduces the analysis overhead time. In addition, if a pressed pellet sample should be broken due to the evacuation action, the failure happens inside the pre-evacuation chamber and the optical main chamber is not contaminated.

The system software is designed for ease of use in routine analyses. The Flowbar in quantitative analysis guides users in establishing calibration. The Easy Analysis and the Program Operation help operators carry out daily analysis easily and smoothly.

Sample preparation

A series of reference materials of cement raw meal certified by CSBTS were used for calibration. Cement raw meal powders, previously pulverized, were pressed into aluminum rings at 120 kN.

Measurement

Measurements were performed on the ZSX Primus III+ with a 3 kW Rh-target X-ray tube. The measurement condition is shown in Table 1.

Table 1: Measurement condition

| Path atmosphere | Vacuum |

| Tube condition | 50 kV and 50 mA |

| Analysis area | 30 mm in diameter |

| Element | Si | Al | Fe | Ca | Mg |

| Line | Kα | Kα | Kα | Kα | Kα |

| Primary filter | Out | Out | Out | Al25 | Out |

| Slit | S4 | S4 | S2 | S4 | S4 |

| Crystal | PET | PET | LiF(200) | LiF(200) | RX25 |

| Detector | F-PC | F-PC | SC | F-PC | F-PC |

| Counting time (s) | 6 | 6 | 6 | 4 | 10 |

| Element | S | Na | K | Ti | Cl |

| Line | Kα | Kα | Kα | Kα | Kα |

| Primary filter | Out | Out | Out | Out | Out |

| Slit | S4 | S4 | S4 | S2 | S2 |

| Crystal | PET | RX25 | LiF(200) | LiF(200) | PET |

| Detector | F-PC | F-PC | F-PC | F-PC | F-PC |

| Counting time (s) | 6 | 10 | 6 | 6 | 10 |

The RX25 multilayer analyzing crystal, included in the standard configuration, has high sensitivity for Mg and Na and is capable of eliminating higher-order lines such as Ca-Kα-3rd which would interfere with Mg-Kα.

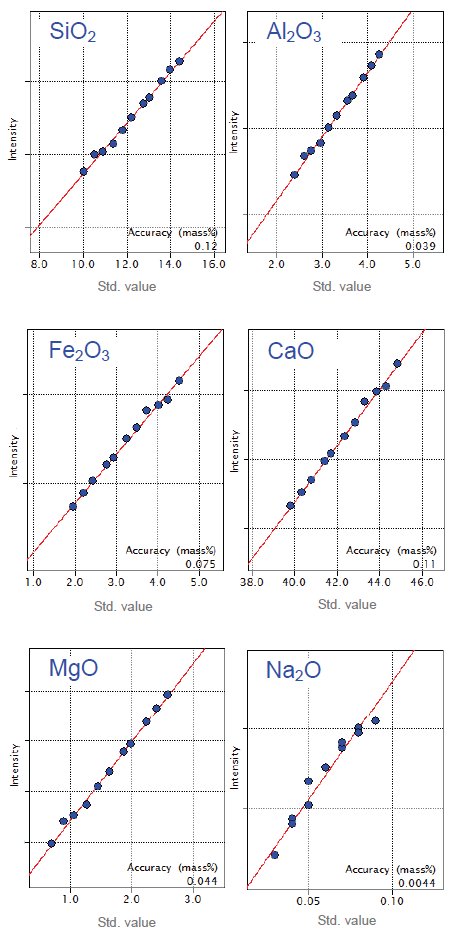

The calibration results are tabulated in Table 2 and the calibration curves for the representative analytes are shown in Figure 1.

Figure 1: Representative calibration curves for cement raw meal

The accuracy of calibration is calculated by the following formula,

$Accuracy = \sqrt{ \frac{\sum_i{(C_i-\hat{C}_i)^2}}{n-2} }$

$C_i$: calculated value of standard sample

$\hat{C}_i$: reference value of standard sample

n : number of standard samples.

Table 2: Calibration results

| Element | Calibration range | Accuracy |

| SiO₂ | 10.05 – 14.43 | 0.12 |

| Al₂O₃ | 2.41 – 4.27 | 0.039 |

| Fe₂O₃ | 1.96 – 4.52 | 0.075 |

| CaO | 39.84 – 44.84 | 0.11 |

| MgO | 0.69 – 2.59 | 0.044 |

| SO₃ | 0.06 – 0.24 | 0.0079 |

| Na₂O | 0.03 – 0.09 | 0.0044 |

| K₂O | 0.14 – 0.30 | 0.0039 |

| TiO₂ | 0.16 – 0.25 | 0.0042 |

| Cl | 0.004 – 0.286 | 0.018 |

Repeatability test

One of the reference materials used for the calibration was measured consecutively 10 times to demonstrate the performance of the ZSX Primus III+ with regard to short-term stability. The test results, tabulated in Table 3, prove that it is possible to analyze pressed pellet samples of cement raw meal with high repeatability on the ZSX Primus III+.

Table 3: Repeatability test results

| Analyte | Std. value | Average | Std. dev. | RSD% |

| SiO₂ | 12.76 | 12.78 | 0.016 | 0.12 |

| Al₂O₃ | 3.56 | 3.56 | 0.0048 | 0.14 |

| Fe₂O₃ | 2.94 | 2.92 | 0.0047 | 0.16 |

| CaO | 41.74 | 41.70 | 0.012 | 0.029 |

| MgO | 1.87 | 1.85 | 0.0078 | 0.42 |

| SO₃ | 0.17 | 0.18 | 0.0016 | 0.86 |

| Na₂O | 0.07 | 0.07 | 0.0008 | 1.1 |

| K₂O | 0.24 | 0.24 | 0.0003 | 0.13 |

| TiO₂ | 0.22 | 0.21 | 0.0009 | 0.44 |

| Cl | 0.179 | 0.205 | 0.0008 | 0.38 |

Conclusion

Cement raw meal samples can be routinely analyzed with high accuracy and precision on the ZSX Primus III+ by the pressed powder method, simple sample preparation.

The ZSX Primus III+ is suitable to powder sample analysis owing to its tube-above optics and functions for measuring pressed pellet samples securely.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.