Characterizing the Thermal Degradation of Polymer

Introduction

The detection or analysis of the gases evolved during a chemical reaction, as a function of temperature, constitute the techniques of thermal analysis called evolved gas detection (EGD) and evolved gas analysis (EGA), respectively.

Thermal analysis using mass spectrometry covers a large number of related and analytical powerful techniques such as evolved gas analysis using mass spectrometry (EGA-MA) including thermogravimetry-mass spectrometry (TG-MS), temperature programmed pyrolysis-mass spectrometry and temperature programmed desorption mass spectrometry.

In conventional EGA-MS, the evolved gaseous products, which are introduced rapidly to MS, are generally ionized by electron ionization (EI) at 70 eV. In this case, a part of the evolved gaseous molecular ion undergoes further decomposition, and observed simultaneously ions. Especially in the thermal processes, since the evolved gases consists of multiple gaseous species in almost all cases, the resulting fragment ions are overlapped, while the fragment ions provide significant information concerning the structure of the molecule, the apparent mass spectra can be quite complicated. In order to differentiate in real-time the multiple organic species that are evolved in the thermal process, one feasible approach is the use of MS with a selective and soft (fragment-free) ionization technique which avoids fragmentation during ionization.

Nylon is a polyamide consisting of several amides linked aliphatic monomers and is valued for its light weight, incredible tensile strength, durability, and resistance to damage. We studied Nylon 12 employing the skimmer-type TG-DTA-PIMS (photo ionization mass spectrometry), which is used to measure without heat history and discriminate the evolved gases in real time. This is the best measurement method for characterizing thermal degradation of materials.

Instrument: ThermoMass Photo

ThermoMass Photo is an evolved gas analytical system designed for real-time simultaneous measurements of thermogravimetry – differential thermal analysis (TG-DTA) coupled with electron impact ionization (EI) and the fragment-free photoionization (PI) mass spectrometry (MS) that performs measurements as a function of temperature or time.

Measurement and analysis

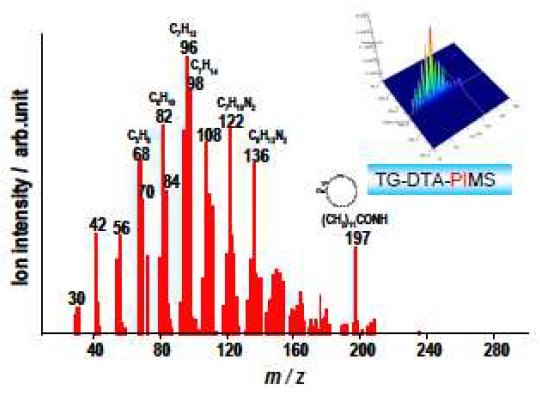

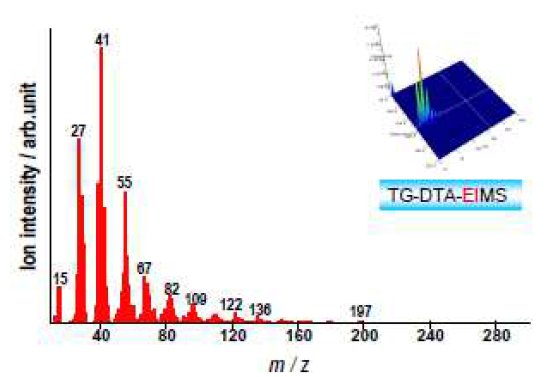

A comparison between the results from EIMS and PIMS for pyrolysate of Nylon 12 obtained by TG-DTA-EI/PIMS is shown in Figure 1.

It is difficult to individually characterize each pyrolysate in the spectrum acquired with the EI method because of mutually overlapping fragment ions in the lower m/z region. On the other hand, the PI method can be discriminated the decomposition of component on spectrum directly because this method inhibits the fragmentation of the molecules during ionization, and detects the molecular ion of decomposition which oriented among backbone structure of samples. Hence in the results, the pyrolysates are detected as the molecular ions such as m/z 197 that originate directly from the structure of Nylon 12. Thus, the characteristic of PIMS fragment free detects minute changing among samples, it is useful to the decomposition characterizing of the sample directly.

As monomers, Nylon 6, Nylon 11, and Nylon 12 are identified as on mass spectrum for ε-caprolactam of m/z 113 (Carbon number: 6), undecane of m/z 183 (Carbon number: 11) and lauryl lactam of m/z 197 (Carbon number: 12) respectively.

Thus, as shown in this fingerprint analysis, the unique feature of PIMS allows easy differentiation of Nylons, and it is useful to detect a minute change among the samples.

%20curves%20(EI).jpg?width=522&height=365&name=TA-6008%20Figure%201a%20TG%2c%20DTA%20and%20TIC%20(total%20ion%20current)%20curves%20(EI).jpg) TG, DTA and TIC (total ion current) curves (EI)

TG, DTA and TIC (total ion current) curves (EI)

PI mass spectrum at 460°C

PI mass spectrum at 460°C

EI mass spectrum at 460°C

EI mass spectrum at 460°C

Figure 1: Comparison of TG-DTA-EI/PIMS curves and mass spectrum for Nylon 12 in inert atmosphere

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.