Evaluation of O-ring by Low-temperature TMA

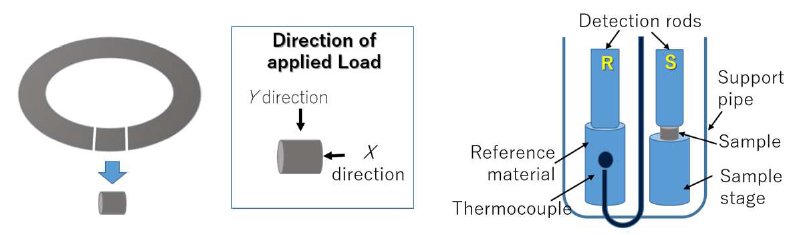

Fluoroelastomer O-rings are noted for their resistance to high temperature and to a wide variety of chemicals. In this application, we demonstrate the use of low temperature TMA with differential type compression loading attachment to evaluate the mechanical properties of an O-ring measured in the X and Y direction.

Thermomechanical analysis (TMA) is a method in thermal analysis that determines the mechanical property of a material by evaluating the change in length as a function of temperature or time. A differential type compression loading method is especially effective for measuring small-sized sample with high accuracy.

Measurement and results

Two portions cut from an O-ring, each with a length of <2 mm for the X and Y direction measurements were utilized in this experiment. Each sample was loaded at room temperature in a differential type compression loading attachment on a TMA8311 equipped with a refrigerator cooling unit. The schematic diagram is illustrated in Figure 1. First and second heating was performed in each sample from -50℃ up to 100℃ heating at 10℃/min and applying a constant load of 20 mN.

Figure 1: Schematic diagram of O-ring, direction of applied load and TMA with differential compression loading attachment

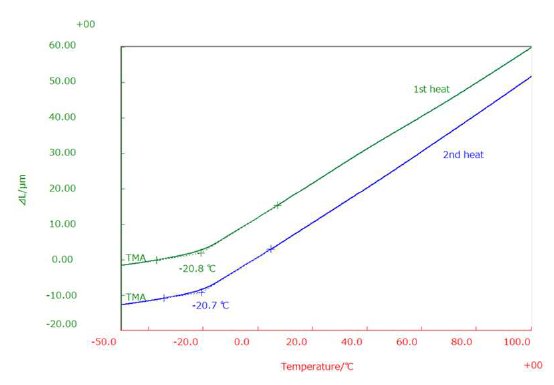

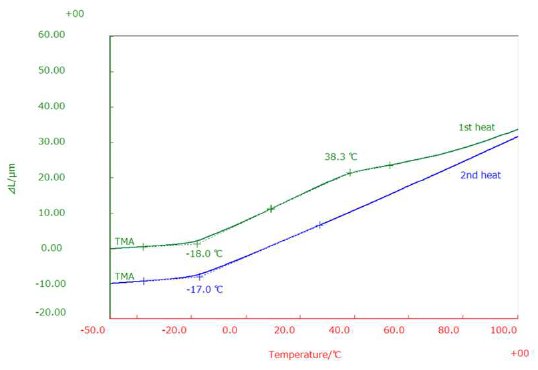

The TMA measurement result of O-ring with a load applied in the Y direction is shown in Figure 2 and the X direction in Figure 3. Figure 2 results show that thermal expansion was observed immediately after the start of the measurement and that the thermal expansion in the sample drastically increased due to glass transition phenomena at -21℃ in both first and second heating results. On the other hand, the same trend was observed when the load was applied in the X-direction (Figure 3) except that an inflection point at 38℃ was detected which is not observed in the second heating result. This is due to the effect of thermal hysteresis of the material in which we can conclude that the material was stretched in the X-direction during the manufacturing process.

Figure 2: TMA measurement results in the Y direction

Figure 3: TMA measurement results in the X direction

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.