XtaLAB Synergy-ED: A True Electron Diffractometer

Introduction

Recognizing the potential of MicroED, Rigaku and JEOL announced a collaboration in 2020 to develop a new product designed in a fashion that will make it easy for any crystallographer to use. The resulting product is the XtaLAB Synergy-ED, a new and fully integrated electron diffractometer, that creates a seamless workflow from data collection to structure determination of three-dimensional molecular structures. The XtaLAB Synergy-ED combines core technologies from the two companies: Rigaku’s high-speed, high-sensitivity detector (HyPix-ED), and instrument control and single crystal analysis software platform (CrysAlisPro ED), and JEOL’s expertise in generation and control of stable electron beams.

There are many materials that only form nanosized crystals. Before the development of the MicroED technique, synthetic chemists were forced to rely on other techniques, such as NMR, to postulate 3D structure. Unfortunately, for complicated molecules such as natural products, the NMR results can be difficult to interpret. MicroED has thus become a revolutionary technique for the advancement of structural science.

MicroED/3DED

The ground-breaking publication1 concerning 3D structures from nanocrystalline lysozyme using electron diffraction in 2013 led to a surge in research around the world in applying the MicroED technique to other nanocrystalline materials.

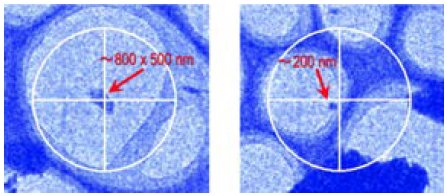

MicroED or 3DED uses electrons instead of X-rays for diffraction experiments. Electron diffraction provides researchers with the ability to perform single crystal diffraction on samples smaller than those at the limit of X-ray diffraction, at around 1 μm. However electrons interact very strongly with matter, imposing an upper limit on the size of samples that can be studied. MicroED also presents experimental challenges that are different than X-ray crystallography which is why the two techniques complement one another to provide structural scientists with enhanced capability. Challenges in microED are:

- Absorption: It typically takes only a very small crystal to completely stop the beam. Sample selection is often counter-intuitive to those experienced in X-ray diffraction experiments as smaller is quite often better.

- Dynamical Diffraction: The electron beam is diffracted multiple times on its path through the crystal. The thicker thecrystal, the more dynamical effects can cause problems for your structure solution and refinement.

- Sample Decay: Exposing a crystal to a high-power, highly charged beam tends to cause rapid crystal decay. This can be mitigated by utilizing low temperature data collection as well as properly selecting the beam intensity and the scan speed.

- Environment: Diffraction experiments must be performed in a vacuum. Gas in the path of the electron beam will absorb and diffract it. It doesn’t take much air to stop the beam or ruin your experiment.

Typical sample sizes for electron diffraction range from tens of nanometres up to a few hundred nanometres.

For the best results small samples are best but as with X-ray experiments, sample composition plays a role.

Software

The software for selecting samples and measuring electron diffraction data on the XtaLAB Synergy-ED is all incorporated into CrysAlisPro ED, giving the user an effortless workflow from selecting the crystal all the way to solving and refining the structure. For those familiar with our X-ray instrumentation CrysAlisPro operates in the same way with some modifications to handle sample finding and centring.

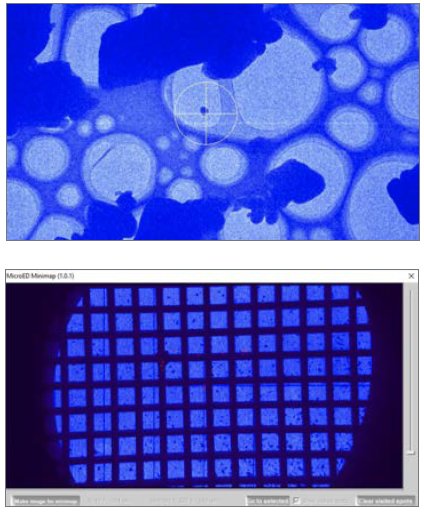

Find samples by browsing sample grids with a simple point and click interface. For longer range navigation our novel mini-map gives you a low magnification map of your sample grid and remembers the areas you’ve looked at.

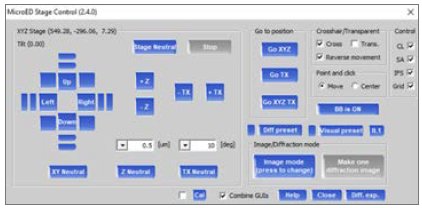

Once you’ve found a sample you are interested in, move it to the beam and centre it just by clicking on it or use the GUI for manual control.

CrysAlisPro allows you to group experiments by grid so you can keep your experimental data organized and setting up data collection is simple.

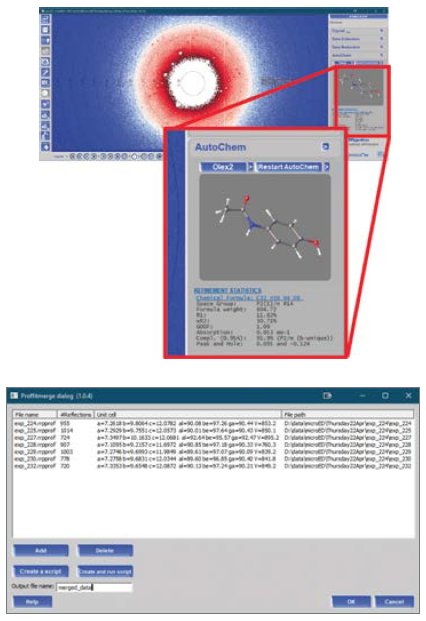

The diffraction experiment proceeds just like an X-ray experiment. This means that, during data acquisition, concurrent automatic data processing occurs, corrections are automatically applied and AutoChem can be used on your MicroED data. AutoChem is the ultimate productivity tool for small molecule chemists, offering fast, fully automatic structure solution and refinement during data collection. AutoChem is seamlessly integrated within CrysAlisPro ED.

One difference in MicroED compared to X-ray diffraction is that due, to the mounting approach, there is limited sample access and it is often necessary to merge the data from multiple grains to get the completeness to an acceptable level. Dataset merging is easy in CrysAlisPro ED with a GUI where multiple datasets can be selected to merge. The merged data is then refinalized to apply all corrections and scaling to get your final hkl reflection file.

Any researcher with experience in measuring single crystal X-ray diffraction data and solving crystal structures should be able to sit down on the first day and perform a MicroED experiment with the XtaLAB Synergy-ED.

Above: The point and click interface in CrysAlisPro (crosshair diameter is 4 μm at the shown zoom level); the mini-map feature for long range navigation; and the GUI based grid navigator.

Below: AutoChem in progress during a microED data collection; the dataset merging tool in CrysAlisPro.

Hardware

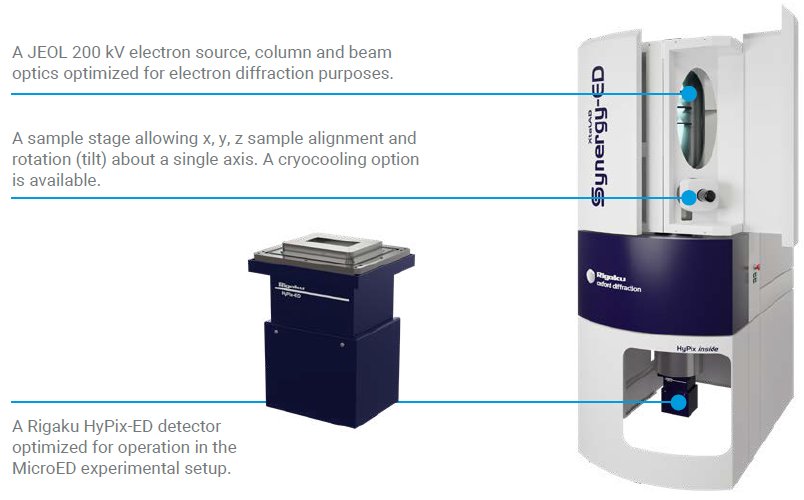

Our solution is an electron diffractometer with a JEOL electron source and optical system operating at 200 kV which uses the rotation method for experiments, providing a familiar approach to data collection and data processing for those familiar with X-ray diffraction experiments.

Building on decades of experience of achieving the high precision needed in the closely related electron microscopy field, our diffractometer uses the same vertical arrangement of the vacuum column which ensures the sample stays in the beam throughout the scan has the additional benefit of providing a compact footprint similar to an X-ray diffractometer.

Our sample stage allows x, y, z and tilt, to allow for precise positioning of your chosen sample and data collection using the rotation method. For sensitive samples, which require stabilization either against the vacuum or to limit beam damage using low temperature measurement, a cryo-transfer sample holder is optionally available.

The detector used within is the HyPix-ED, a close relative of the detectors used in our single crystal X-ray diffraction equipment, but optimised for electron diffraction. The HyPix-ED features the same event driven counting that allows for ultra-low noise, with zero dark noise and zero readout noise enabling high frame rates and high data quality.

Results

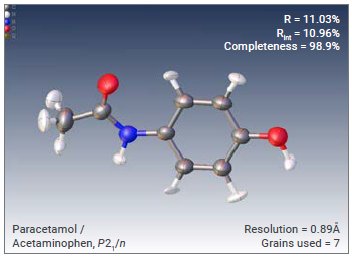

We have now collected data on many samples using the XtaLAB Synergy-ED. In general it is normally possible to see hydrogenpositions in the difference map. Here is a selection of some of the results.

Paracetamol

The structures solved and refined in this section were refined using SFAC instructions suitable for electron diffraction. In some cases a single grain was able to provide sufficient completeness for a structure solution, whilst for other samples multiple grains were used. All structures were collected using the XtaLAB Synergy-ED, processed with CrysAlisPro ED and solved and refined either with AutoChem or Olex2.

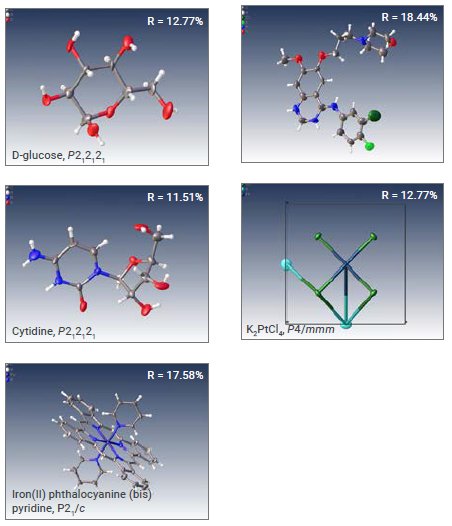

Other examples collected on the XtaLAB Synergy-ED (in brief)

Some examples of our first attempts at solving structures with data collected on the XtaLAB Synergy-ED including pharmaceutical compounds, inorganic materials and complexes ranging from triclinic to tetragonal symmetry.

Authors

Fraser White¹, Mathias Meyer², Michał Jasnowski², Akihito Yamano³, Sho Ito³, Eiji Okunishi⁴, Yoshitaka Aoyama⁴, Joseph Ferrara⁵

¹Rigaku Europe SE - Neu-Isenburg, Germany, ²Rigaku Polska - Wrocław, Poland, ³Rigaku Corporation - Haijima, Tokyo, Japan, ⁴JEOL Ltd. - Akishima, Tokyo, Japan,

⁵Rigaku Americas Corporation, The Woodlands, TX, USA

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.