Quantitative Analysis of a 4-component Sample

Introduction

In the past, quantitative analysis with X-ray diffractometry was performed using calibration curves, but due to the progress of computers and analysis software, quantitative analysis using the WPPF (Whole Powder Pattern Fitting) method has now come into wide use. In the WPPF method, profile fitting is performed over a comparatively broad angular range, based on information involving the crystal system and lattice constants. Since diffraction intensity can be refined at the same time as the diffraction angle, quantitative analysis can be done without the need for calibration curves. Previous benchtop X-ray diffractometers needed a measurement time of roughly 1-2 hours to measure an X-ray diffraction pattern with the wide angular range and sufficient intensity necessary for quantitative analysis. However, with a benchtop X-ray diffractometer equipped with a high-speed 1-dimensional detector, it is possible to obtain an X-ray diffraction pattern suitable for quantitative analysis in about 10 minutes.

Measurements and results

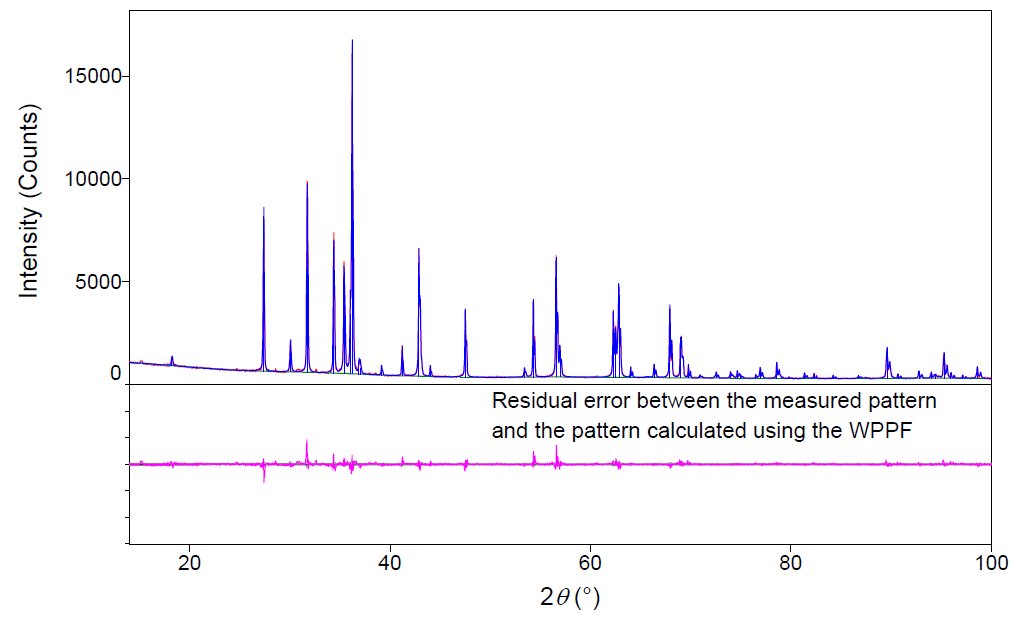

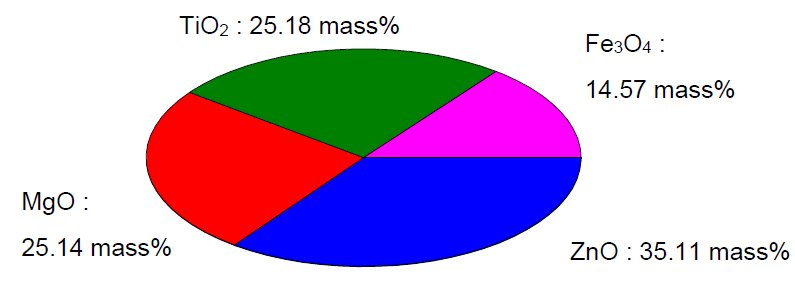

When a sample comprised of four components was measured at a scanning speed yielding a measurement time of about 10 minutes, the maximum intensity peak in the X-ray diffraction pattern exceeded 10,000 counts, and diffraction intensity sufficient for analysis using the WPPF method was obtained. As shown in Figure 1, when analysis was conducted using the WPPF method, the obtained analysis results were extremely close to the sample preparation values, as indicated in Table 1 and Figure 2.

Figure 1: Analysis results using the WPPF method for a powder sample comprised of four components

Figure 2: Graph of quantitative results obtained using the WPPF method

Table 1: Components of the measurement sample the results of quantification using the WPPF method

| Components | Amounts of preparation | Quantitative value (%) |

| ZnO | 35.8 | 35.11(10) |

| MgO | 26.3 | 25.14(17) |

| TiO₂ | 24.7 | 25.18(10) |

| Fe₃O₄ | 13.2 | 14.57(10) |

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.