Polymers and Fibers

Additives, crystalline-to-amorphous ratio and orientation

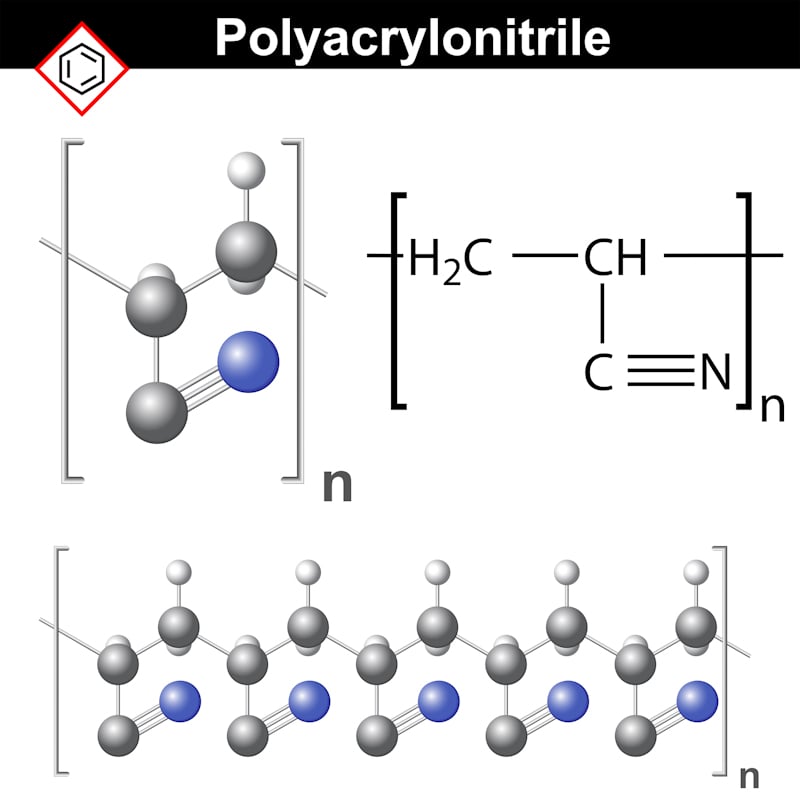

Many plastic polymers and fibers have some order and can be identified and studied by X-ray diffraction methods. These polymers are, at least in part, crystalline or pseudo-crystalline with partially ordered structures which cause diffraction peaks. In fact, the percent crystallinity in a polymer can be determined by X-ray diffraction methods. This crystalline/amorphous ratio is often related to processing methods and is of much importance in polymer chemistry.

Other uses of XRD in plastics and polymers research and production include: determination of unit cell type and lattice parameters, determination of the microstructure, and determination of crystallographic orientation through pole figures.

During development and production, the compounds in polymers have to be controlled strictly to meet the national and international regulations avoiding potential danger due to hazardous and toxic substances. Directives for the Restriction of Hazardous Substances (RoHS), as well as End of Life Vehicle (ELV), include restrictions for the use of cadmium (Cd), mercury (Hg), lead (Pb), chromium (VI) (Cr) and poly-brominated (Br) flame retardants (PBB and PBDE) in order to mitigate potential risks to health or environment. For all tasks in polymer R&D and production, X-ray fluorescence (XRF) spectroscopy can identify and quantify concentrations of the aforementioned additives—as well as antimony, barium, calcium, copper, phosphorus, titanium, zinc and all other elements from sodium through uranium.

Application notes

The following application notes are relevant to this technique

Rigaku recommends the following systems

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.