From Si on plastic to semiconductor wafer stacks

Every aspect of modern life benefits from coating or thin film technology. Whether a barrier layer film in an integrated circuit chip or a conversion coating on an aluminum beverage can, X-ray analytical techniques are integral to both R&D development, production process control and quality assurance. X-ray fluorescence (XRF) can determine the thickness and elemental composition of metallic coatings. Commonly employed in the semiconductor manufacturing process as a metrology tool, X-ray reflectometry (XRR) is used to measure layer thicknesses in a multi-layer stack of coatings and also can characterize other coating properties like roughness and interlayer diffusion. Emerging as a leading enabler for nano-technology research, X-ray diffraction (XRD) and associated techniques are employed to examine the nature of the molecular structure of films. Rigaku technology and experience provide a variety of non-destructive analytical solutions for coating and thin film measurements.

Application Notes

The following application notes are relevant to this industryXRD

EDXRF

Process

Total reflection XRF (TXRF)

Rigaku recommends the following systems:

WDXRF

Benchtop tube below sequential WDXRF spectrometer analyzes O through U in solids, liquids and powders

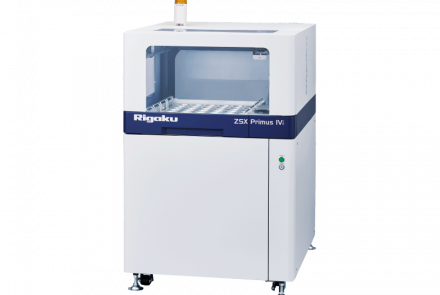

High power, tube above, sequential WDXRF spectrometer with new ZSX Guidance expert system software

High-power, tube-below, sequential WDXRF spectrometer with new ZSX Guidance expert system software